Blog

Infographic: Computer System Validation Vs. Computer Software Assurance

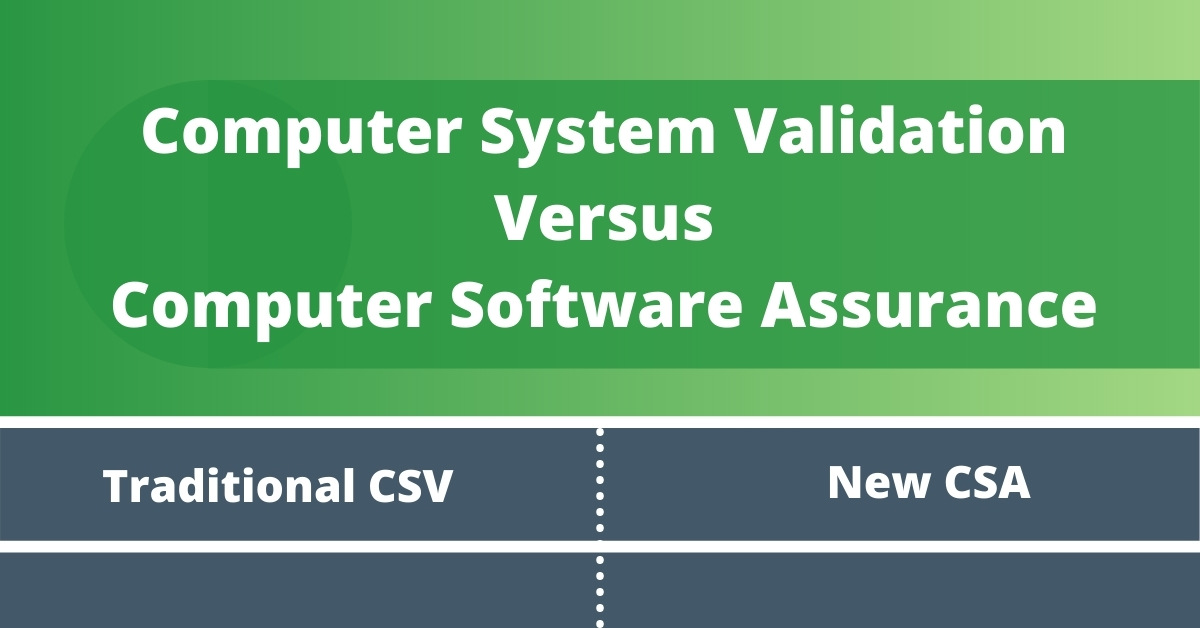

The FDA (US Food and Drug Administration) is due to release guidance on Computer Software Assurance. That guidance aims to put critical thinking at the centre of Computer System Validation (CSV) processes.

In our latest infographic, we highlight the main differences between traditional CSV and the new Computer Software Assurace (CSA) approach.

Traditional CSV

- Perceived as a barrier to automated solutions and innovation

- All software validated as if it’s product software

- The primary focus is securing evidence for auditors

- Duplication of vendor documentation and effort

- High occurrence of deviations due to tester error

New Computer Software Assurance

- A more flexible, less burdensome, and faster risk-based approach

- Various assurance approaches depending on the system/feature risk

- Apply critical thinking to ensure the software is safe and meet its intended use

- Reduced testing activities resulting from better supplier qualification and collaboration

- Reduced number of deviations due to tester error

Is Your Company Ready for the FDA’s Upcoming Guidance on Computer Software Assurance?

Technology and computerised systems have evolved greatly over the past 20 years. In that time, cloud computing has become mainstream, and big data is here. When you also add the fourth industrial revolution (Industry 4.0), it’s clear that new manufacturing and business technologies will be truly transformative in the coming years.

Yet, in the Life Sciences industry, the uptake of new automated solutions and technologies has been slow relative to other manufacturing industries. It is a trend that regulators have been seeking to fix.

The FDA’s Case for Quality initiative was set up to promote industry collaboration and encourage innovation, automation, and digital technologies. By working with those in the industry, the FDA was able to identify best practices and learn the barriers that exist for manufacturers.

It quickly became apparent that CSV, as it is applied today, is perceived as a barrier to technology implementation, where companies produce excessive, non-value-adding documentation that is driving longer validation cycles and increasing expenses.

Manufacturers are reluctant to invest in highly automated technologies as the validation cost is so high. It has become clear that the approach to validating such computer systems has not kept pace with technology advancements.

Enter Computer Software Assurance (CSA), the FDA’s upcoming guidance that aims to place critical thinking at the centre of the CSV process.

What is CSA?

Computer Software Assurance is a risk-based approach to computerised systems that is product quality-focused and patient-centric. It encourages critical thinking based on product knowledge.

The FDA, recognising that CSV has become a barrier to technology, is releasing the new guidance to tackle the issues faced by manufacturers, while also offering greater flexibility in achieving software assurance.

The guidance highlights new ways of approaching non-product software, i.e., QMS, ERP, PLM, MES, LIMS, etc. It states that assurance activities should be value-driven, patient-focused, and streamlined using existing technologies such as automated testing tools.

Here are some areas that the new guideline seeks to address.

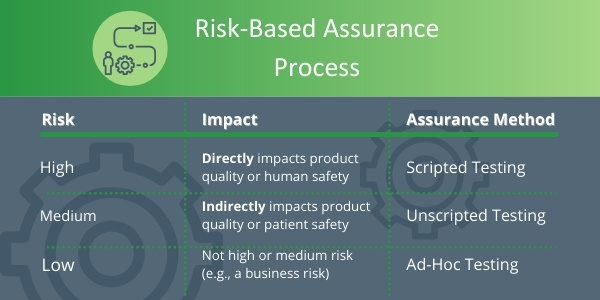

Risk-Based Approach

A risk-based approach to validation is not a new concept. However, regulated companies have struggled with balancing the overall validation effort based on the software risks identified. As a result, companies fall into the trap of applying a one-size-fits-all CSV approach, where lower-risk systems are evaluated to the same scrutiny as high-risk systems. This approach produces a burdensome level of documentation, drives longer validation cycles, and increases expenditure.

The new guidance advocates a risk-based validation approach and also switches the focus from validation to assurance.

How will this affect you? One of the main areas is that there will be a significantly reduced validation requirement for software applications that have no direct impact on product quality or safety. In this situation, the recommendation from the FDA is to use current processes like the qualification of suppliers, as well as risk-mitigating process controls.

Vendor Qualification

Even with an audited or trusted vendor, regulated companies still tend to reproduce documentation and test out-of-the-box software functionality that has already been tested by the vendor. Under the new guidance, if a vendor’s documentation is deemed to be of good quality, efforts should focus on ensuring the software meets its intended use rather than reproducing documentation for the sake of audit readiness.

Testing

With traditional CSV, regulated industries have adopted a conservative approach to testing, where too much focus is on documentation, manual testing, and evidence gathering. It is common to see this robust and scripted test approach applied to every system and function, regardless of its associated risk classification.

There is more flexibility with the assurance approach that CSA facilitates, as well as flexibility with acceptable records of results. There is also the introduction of the terms Scripted, Unscripted, and Ad Hoc Testing.

Scripted Testing

Scripted testing is widely used today in traditional CSV. It contains test objectives, step-by-step test procedures, expected results, independent review, and approval. CSA guides companies to continue using Scripted testing but only for high-risk features of a system that directly impact the product or patient safety.

Unscripted testing

An Unscripted test is testing without detailed instructions but with a clear objective and pass/fail criteria. Unscripted testing is to be used to test lower risk features of a system. Importantly, Unscripted testing still means you have to test, and details of test failures should be recorded as normal.

Ad Hoc Testing

Ad Hoc testing is similar to Unscripted Testing but does not require pre-approved protocols. This assurance approach may be in the form of exploratory testing, and it is considered the least-burdensome assurance option. It should be used for low-risk systems.

Efficiency Savings that Will Increase Innovation

By applying critical thinking and a risk-based approach, these assurance processes can be easily implemented on a feature-by-feature basis, as shown by the simple example illustrated below.

Unscripted and Ad-Hoc testing are seen as the right level of documentation for medium to low-risk features. CSA will consider these approaches to be an acceptable record or results. It is expected this new approach will result in a 30 – 50% reduction in time and costs, so it will therefore increase and accelerate innovation.

Preparing for CSA

The new CSA guidance is expected to be released in the coming months. The FDA has stated that companies can (and should) proactively take these principles into consideration. The recommendation is to create a transition plan and to pilot new methodologies on a subgroup of systems before rolling out to your entire organisation.

For some companies, moving to CSA will be a cultural shift compared to the current way of doing things. It is therefore critical the quality leadership team embrace CSA to enable its adoption throughout the organisation.

Now is also the perfect time to leverage automated testing and continuous data monitoring tools to streamline assurance activities that the new guidance supports.

Conclusion

Digital transformation is gathering pace in the life sciences industry due to Industry 4.0. The COVID-19 crisis is also spurring on innovation.

Traditional CSV practices are no longer compatible with emerging automation and digital technology solutions. It is time to implement a streamlined validation approach based on critical thinking that will support Industry 4.0 and will ultimately drive better patient outcomes and faster time to market.

How Industry 4.0 Supports Flexibility and Mass Customisation

“Any customer can have a car painted any colour that he wants so long as it is black.”

That’s a quote from Henry Ford, the founder of the Ford Motor Company. It’s a famous quote, but what does it have to do with flexible manufacturing and mass customisation? Does it have any relevance in the era of Industry 4.0 as we look towards the next industrial revolution, Industry 5.0? Is there anything we can learn from an idea that appears so outdated?

According to his autobiography, Ford made the famous comment in a meeting with his team in 1909. The comment was part of an announcement that the Ford Motor Company would, from then on, only be making one model of car – the Model T.

Ford’s thinking at the time was clear. In another part of his autobiography, Ford writes:

“No business can improve unless it pays the closest possible attention to complaints and suggestions. If there is any defect in service then that must be instantly and rigorously investigated, but when the suggestion is only as to style, one has to make sure whether it is not merely a personal whim that is being voiced.”

So, Ford’s approach was to get the design of the product right and then manufacture that product and that product alone at a massive scale.

It was a successful approach, too. When he made the famous “any colour so long as it’s black” quote, Ford was producing just over 10,000 cars a year. Ten years later, the company had produced half-a-million Model T Fords, and five years after that, it was producing two million.

100+ Years On

Industry 4.0 technologies are changing the reality from Ford’s era unlike any other technologies that have come before. Today, for example, it is now possible to meet the demands of customers for product customisation while also getting the design right.

In the life sciences sector, that means customised medicines, therapies, and medical devices that meet quality standards and regulatory requirements, while also being economical to produce.

It’s also possible to have a flexible production process where different products with different tools and moulds can be produced on the same production line.

For example, dynamically programmed robots with interchangeable tooling enable manufacturers to quickly and effectively switch between models manufactured with negligible efficiency loss.

Industry 4.0 technologies, processes, and ways of thinking make this possible.

Crucially, it’s also possible to do all the above while maintaining productivity and operational efficiency. As a result, new profit-making opportunities become a reality.

What is Mass Customisation?

Mass customisation is the ability to manufacture what the customer wants profitably and with no loss of productivity. The aim is to make the manufacturing process more customer oriented.

What is Flexible Manufacturing?

Flexible manufacturing is a manufacturing strategy involving production lines that can quickly and easily change the type of product being produced. The process of switching between product types is automated.

The Technologies Driving Change

Back in Ford’s day, designers designed products with minimal input from consumers. Engineers then worked on refining the design and getting the production processes right, in addition to making sure the production process was as effective and efficient as possible.

The product then left the production line and entered the distribution chain, with little connection between it and the factory floor.

In other words, the connection between the customer, the manufacturing process, and the design process, was minimal. The supply chain was also disconnected and disjointed.

Industry 4.0 turns this completely on its head. Sensors and communication technologies mean machines in the production line can interact, collect data, and issue instructions autonomously. These processes can be integrated with the supply and distribution chains, connecting other business units, and driving efficiency savings even further. Supply chain collaboration and oversight, product traceability, OEE optimisation, and more happen in real-time.

However, the real gamechanger when it comes to flexibility and mass customisation is the use of sensors in end products. With this technology, manufacturers can create digital twins of products that are being used by customers in the real world, with the digital twin receiving real-time updates from sensors on the physical products.

Non-Linear Product Lifecycle

Digital twin and simulation technologies offer a number of benefits to manufacturers, including predictive maintenance and making faults easier and faster to repair.

One of the biggest benefits, however, is how the use of sensors and digital twin technologies can influence the design process. Product designers no longer have to rely on gut instinct, limited research, or outdated usage data.

With Industry 4.0 technologies like digital twins, designers can use real-time data to produce products that customers really want.

In other words, the product lifecycle becomes non-linear.

A non-linear product lifecycle makes it possible to customise products for different customer segments, improving customer relations and the customer experience. Even single-unit production runs are possible, i.e., true product personalisation.

Mass Customisation Gets You Closer to Your Customers

Remaining competitive and relevant to your customers is essential, as is improving the customer experience, from the service they receive to shipping lead times to product quality.

Arguably, however, the most eye-catching benefit of mass customisation and manufacturing flexibility has to do with the relationship you have with customers. Industry 4.0 technologies, as well as mass customisation and flexible manufacturing strategies, get you closer to customers.

As a result, you can establish a more robust direct link with customers, strengthening your brand, building customer loyalty, improving customer and marketplace knowledge, and ensuring you stay out in front of emerging trends, changing values, and evolving expectations.

What Can We Learn from Ford’s Famous Quote?

There is a connection between Ford’s approach in the early 1900s and the opportunities presented by Industry 4.0 today. Specifically, two of the biggest things that Ford got right back in 1909 was to:

- Focus on the customer – he understood that the vast majority of his customers preferred to have a reliable car they could afford rather than one where they could specify a particular colour.

- Focus on profitability – Ford also understood he had to deliver on the above expectations of his customers in a way that was profitable for his company.

Hence, the get-it-right-and-then-make-them-all-the-same approach.

Manufacturers need to follow Ford’s lead, albeit with a 21st-century twist.

- Focus on the customer – customers still want products that work, and they want those products to be affordable, but they also want products tailored to their needs, i.e., they want customised products.

- Focus on profitability – manufacturers need to offer flexibility and customisation to remain competitive, but they must do so profitably.

Industry 4.0 technologies make both the above possible: sensors, automation, robotics, machine learning, data analysis (particularly anomaly detection), digital twins, equipment integration, and more.

It is manufacturing’s next evolutionary step, as Industry 4.0 technologies, processes, and systems become the norm, and we start moving towards Industry 5.0.

Top Smart Factory Trends in 2021 for the Life Sciences Sector

It is common to look at the trends that will impact smart manufacturing over the next 12 months and beyond at this time of year. We are in unprecedented times, though, making the manufacturing trends that will impact the life sciences sector in 2021 even more important. Here are some of the key points you should be aware of.

Technologies Used to Adapt to COVID-19 Realities Will Become Mainstream

The COVID-19 pandemic has had a significant influence on the working practices and strategies of organisations across almost all sectors. Companies have had to adapt, whether to survive the pandemic, to deal with increased demand, or to continue operations safely and in adherence with social distancing rules.

Some of those adaptations will continue beyond the pandemic, particularly in relation to technologies and processes used in manufacturing organisations. Two examples are 3D printing and remote support.

3D printing enabled the rapid production of PPE in the early days of the pandemic, demonstrating the potential of this technology. It will continue to be important over the coming years.

Remote support is even more of a game-changer as it provided organisations with a socially distanced solution to dealing with maintenance and other technical issues. The effectiveness of remote support, the cost and time savings involved, and the ability to keep systems secure and compliant, means the use of remote support will continue long after the pandemic has ended.

Mass Customisation Will Continue to Replace Mass Production

Manufacturers in many industries are moving further and further away from mass production models in favour of mass customisation. Mass customisation is made possible through smart factory technologies and solutions and brings a range of benefits to manufacturers in the life sciences sector. Those benefits include bringing you closer to your customers.

Resilience and Flexibility Will Be Prioritised

The COVID-19 pandemic severely tested the resilience and flexibility of organisations in a range of sectors.

Even for manufacturers who remained busy, COVID-19 put a spotlight on resilience and flexibility, in many cases moving both higher up the priority list than things like disaster recovery.

For manufacturers, a key focus for resilience and flexibility is the supply chain. This focus includes taking steps to increase their visibility across all supply chain components.

This enhanced visibility brings additional benefits, too, benefits that are becoming more and more important. An example includes the provenance of materials where there is a growing focus on things like labour conditions and fair trade across all parts of the supply chain.

Building resilience and flexibility into manufacturing supply chains also involves solutions that enable real-time communication and decision making across all supply chain components.

Improved collaboration is seen as essential, too, with the aim of evolving supply chains into collaborative networks rather than connected but independent entities.

Increasing Use of Remote Monitoring & Predictive Analytics

Reducing unplanned downtime has always been a priority for manufacturers. Industry 4.0 technologies help significantly, particularly remote monitoring and predictive analytics technologies.

With these technologies, engineers and technicians can monitor equipment and machines in real-time, identifying maintenance requirements before problems occur. They can then develop potential solutions before they visit the job site, reducing the amount of time they need to be on location.

In fact, the visit to the job site might not even be necessary with the use of remote support processes and technologies, including Microsoft Teams and mixed reality tech.

From a COVID-19 perspective, remote monitoring of machines and predictive analytics also helps pharmaceutical and medical device manufacturers optimise the process of bringing third parties on-site, while also minimising the frequency of these situations from occurring.

Increasing Focus on Data and Ensuring Data Quality

A trend that could be on this 2021 list is the increasing use of AI (artificial intelligence) in manufacturing. While AI offers significant strategic value for pharmaceutical and medical device manufacturers in a range of areas, the potential of AI solutions depends on the quality of data that the algorithms use. So, expect 2021 to be a year of data capture and quality focus.

The Era of the Distributed Cloud

Cloud computing is increasingly becoming the norm in manufacturing organisations, including in the life sciences sector. However, there are still concerns held by many organisations and executives about the security of their data when it is moved off-site to a third-party platform.

The distributed cloud provides a solution to these concerns. With a distributed cloud, you can run the infrastructure of a public cloud in various locations. These locations can include your premises, other data centres, and the infrastructure of your cloud provider. You can then manage and control everything through a single system.

The distributed cloud even makes it possible for manufacturing organisations to utilise the edge cloud, or edge computing. The edge cloud is where computing – applications or servers – run at or close to the source of the data.

Aside from addressing security concerns, distributed cloud and edge cloud technologies help organisations comply with privacy regulations in multiple jurisdictions. The technologies can also improve the real-time processing of large amounts of data.

Upskilling the Workforce Will Be Essential

The automation technologies being deployed in the manufacturing sector are leading to a change in the skills needed on and off the factory floor. Previously, manufacturers needed workers for repetitive tasks. Today, they need knowledge workers, i.e., workers with the skills to implement, operate, and maintain the automation, collaboration, and data-based technologies that are becoming the norm.

So, companies will seek to recruit knowledge workers. However, they are in short supply, so upskilling the existing workforce will also become a priority.

Decreasing Emphasis on Industry 4.0 Driven by an Increasing Focus on Industry 5.0

While Industry 4.0 is still the here and now for many organisations, it is a concept that has been around for several years. Many of the technologies, processes, and systems that make Industry 4.0 solutions possible already exist. They continue to be improved, and new technologies are being developed, but there is now an increasing emphasis on the stage after industry 4.0 – Industry 5.0.

Where Industry 4.0 focuses on digital transformation, particularly through automation, Industry 5.0 is about deepening the integration between people and smart machines/robots. Watch this space.

What is Digital Twin Technology and How It Benefits Manufacturing in the Industry 4.0 Era?

Understanding what is happening now on your production line, and predicting what will happen in the future, is essential for maximising OEE, optimising productivity, and improving business profitability. You can achieve all these things with digital twin technologies.

Digital twin technology is one of the most important Industry 4.0 technologies currently available. Digital twins give you insights into all aspects of your production line and manufacturing process.

You can then use these insights to make better decisions, plus you can automate the decision-making process with the dynamic recalibration of equipment, production lines, processes, and systems.

In other words, digital twins provide engineers with virtual tools that allow them to look at, explore, and assess physical assets, processes, and systems. With this ability, it is possible to get an accurate view of what is happening now, as well as what will happen in the future.

What Is Digital Twin Technology?

A digital twin uses virtual and augmented reality as well as 3D graphic and data modelling to build a virtual model of a process, system, service, product, or other physical object. This digital twin is an exact replica of the physical world. Its exact replica status is maintained through real-time updates.

It is a technology that is applicable to a wide range of environments, including the monitoring of products while they are in use and through the entire product life cycle.

In manufacturing, you can use a digital twin technology at various levels:

- Component level – focused on a single, highly critical component within the manufacturing process.

- Asset level – creating a digital twin of a single piece of equipment within a production line.

- System level – using a digital twin to monitor and improve an entire production line.

- Process level – this looks at the entire manufacturing process from product and process design and development, to manufacturing and production. It also applies to distribution and the use of the finished product by customers/patients throughout the entire life cycle, as well as for the development of future products.

So, A Digital Twin is a Simulation?

Not exactly. A digital twin starts as a simulation, but the difference between a digital simulation and a digital twin is real-time updates.

With a simulation, engineers can run tests and conduct assessments on a simulated version of a physical asset. The simulation is static, however. In other words, it doesn’t keep pace with the physical asset unless the engineer inputs new parameters into the simulation.

A digital twin, on the other hand, receives real-time updates from the physical asset, process, or system. Therefore, the tests, assessments, and analysis work conducted by engineers are based on real-world conditions. As the state of the digital twin dynamically changes as it receives new data from the physical world, it matures, producing outputs that are more accurate and valuable.

How Does Digital Twin Technology Work?

A digital twin comprises three main elements:

- Past data – historical performance data of individual machines, overall processes, and specific systems.

- Present data – real-time data from equipment sensors, outputs from manufacturing platforms and systems, and outputs from systems throughout the distribution chain. It can also include outputs from systems in other business units, including customer service and purchasing.

- Future data – machine learning as well as inputs from engineers.

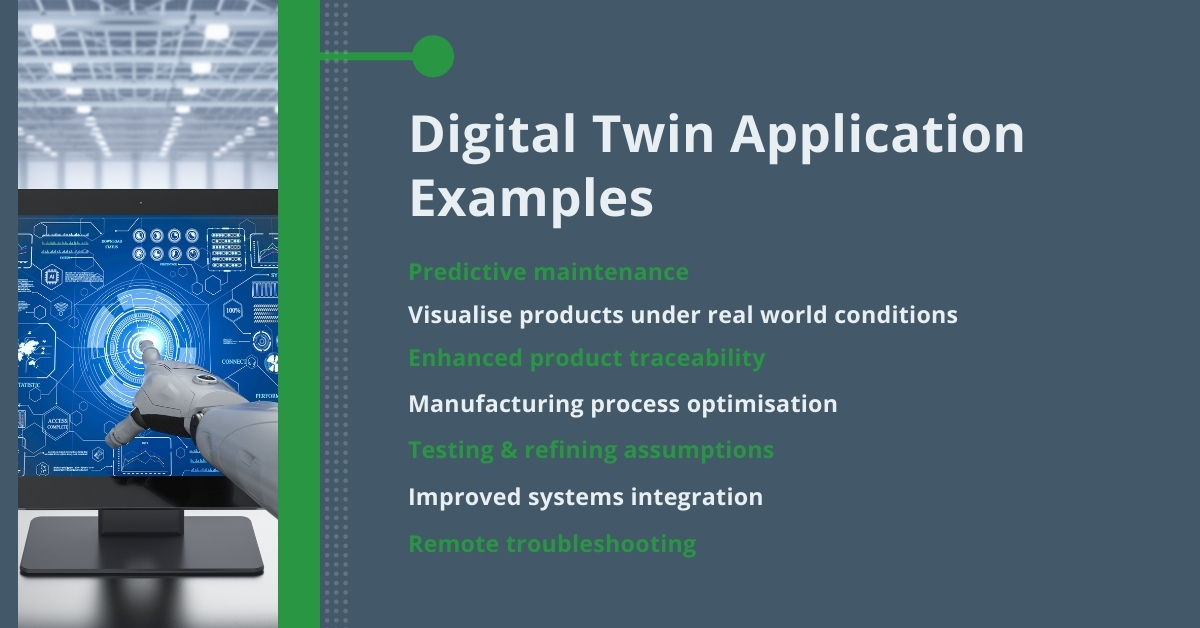

Applications for Digital Twins

Some examples of typical applications for digital twins include:

- Using predictive maintenance to maintain equipment, production lines, and facilities

- Getting a better understanding of products by monitoring them in real-time as they are used by real customers or end-users

- Manufacturing process optimisation

- Enhancing product traceability processes

- Testing, validating, and refining assumptions

- Increasing the level of integration between unconnected systems

- Remote troubleshooting of equipment, regardless of geographical location

What Engineers and Manufacturers Can Do With Digital Twins

First, a digital twin lets you monitor a manufacturing component, asset, system, or process in real-time. This enhanced monitoring capability gives a deeper understanding of what is happening on your production lines and in the wider manufacturing process.

With machine learning and inputs from expert engineers, you can also use the digital twin to identify problems before they occur and predict future outcomes. These predictions include outcomes within existing parameters as well as outcomes if those parameters change.

Digital twin technology supports other Industry 4.0 technologies, too, helping to improve OEE, reduce waste, improve batch changeover times, improve product quality, enhance traceability, and more. It allows for efficient design and development, linking three-dimensional models with simulation and equipment control code emulation.

In addition, having a digital twin enables virtual troubleshooting and support, removing the physical restraints of expert engineers having to be at your location. The technology can also form the basis of customer interactive dynamic supply chains.

Remember, the above includes just some of the things you can achieve using digital twin technologies. There are also manufacturing process development advantages, product development advantages, distribution chain efficiency advantages, and more.

The Benefits of Digital Twin Technology

The benefits that digital twin technologies offer your business include:

- Increased reliability of equipment and production lines

- Improved OEE through reduced downtime and improved performance

- Improved productivity

- Reduced risk in various areas, including product availability, marketplace reputation, and more

- Lower maintenance costs by predicting maintenance issues before breakdowns occur

- Faster production times

- New business opportunities such as mass customisation, mixed manufacturing, small-batch manufacturing, and more

- Improved customer service as customers can remotely configure customised products

- Improved product quality and enhanced insight into the performance of your products in multiple real-time applications and environments

- More efficient supply and delivery chains

- Improved profits

Where to Next?

Digital twin technologies are available now and can bring the above benefits to your business in the short-term as well as the medium and long-term. Plus, the use of digital twins is a growing trend.

To remain competitive, the time to start analysing and implementing this new and potentially disruptive technology is now.

Benefits of Microsoft Azure for Manufacturers in the Life Sciences & Technology Sectors

Implementing Industry 4.0 and smart factory solutions in your manufacturing operation requires a fresh approach to solution delivery, platform implementation, and IT infrastructure. Central to most solutions is the use of cloud technologies, such as Microsoft Azure.

At SL Controls, we have extensive experience working with a range of cloud solution providers. Plus, we offer a service that is platform agnostic.

However, we favour the Microsoft Azure platform for building, deploying, and managing smart factory solutions in the cloud, particularly for companies in the life sciences and technology sectors. This is because of the range of features, scope, and flexibility of Azure, in addition to a range of other factors.

Microsoft Azure – the Basics

At its core, Microsoft Azure is a cloud computing platform. Azure makes it possible to build, implement, and manage solutions in the cloud. This makes Microsoft Azure a blend of platform as a service (PaaS) and infrastructure as a service (IaaS).

With Azure, it is possible to develop solutions that would have traditionally run on servers at your location, as well as new solutions that are only possible because of cloud and Azure-specific technologies.

Of course, Microsoft isn’t alone in the cloud computing market. There is a range of competitors, from new start-ups to some of the biggest companies in the world, including Amazon’s AWS offering and Google’s cloud platform.

Below are some of the reasons our leadership team, senior engineers, and project managers at SL Controls prioritise Microsoft Azure where practical.

Minimises the Hardware You Need On-Site

Production machines, equipment, sensors, platforms, and systems can all be connected to the Azure cloud and integrated to deliver on your requirements.

Hybrid Cloud Compatible

Azure solutions can be developed to meet the needs of your business, whether that means solutions on one cloud, across multiple clouds, at your location, or at the edge (i.e., at or close to the source of your data).

Compliance Compatible

The hybrid computing capabilities of Azure allow you to create private cloud infrastructure using Azure Networking, enabling compliance at all levels. This is particularly beneficial for manufacturers in the life sciences sector, including those in the pharmaceutical and medical device industries.

Familiar Apps

Applications that your company may already use are fully integrated with Microsoft Azure. This includes Outlook, SharePoint, Teams, and Office 365. This reduces the learning curve, so helps with the implementation of new solutions and systems.

The Highest Levels of Security

Starting with password security, Microsoft Azure has a single sign-on feature. This makes it easier to manage large numbers of users. It also makes it easier for people in your organisation to access their platforms, systems, applications, and data without a complex set of passwords to remember.

Plus, you can implement even greater levels of control over access as required. For example, you can make access to parts of your system either device or location-specific, reducing the potential for unauthorised access.

Azure also benefits from Microsoft’s advanced threat management and enterprise-level security.

In addition, Microsoft takes a proactive approach to compliance in relation to its Azure platform, and it invests significantly in security. According to the latest figures from the company, it invests USD $1 billion every year protecting the data of its customers.

High Levels of Flexibility, Helping to Future-Proof Your Organisation

Microsoft Azure is fully scalable according to business requirements as you move further down the digital transformation and Smart Factory journey.

The platform also supports all programming languages and development frameworks, ensuring flexibility in the development process when creating the new solutions that your business needs.

Backup and Data Recovery

Microsoft Azure has a Geo-Redundant Storage feature. This means backups of your data are automatically stored in data centres in a different geographical region than the data centre location of your main system. So, if something happens with the data centres in your region, a backup will still exist.

Continuous Innovation

Microsoft Azure is a core part of the company’s business, and it has committed to continually developing and improving the platform.

Customer-Focused Solutions

At SL Controls, our only goal is to develop solutions that meet your requirements. If you need solutions built on different cloud platforms or technologies, we have the skills and capabilities that are required.

Many companies in the life sciences and technology sectors already use Microsoft platforms, solutions, and technologies, including Azure. This, combined with our experience developing and implementing new and innovative Industry 4.0 solutions, means we have confidence in the Azure platform to deliver on the rapidly evolving requirements of manufacturing companies.

11 Manufacturing / Ramp Strategies that Smart Factory Solutions Facilitate

The manufacturing / ramp strategies in use on your production lines are crucial to the success of your business. Specifically, they enable you to profitably produce the required volume of products and, in most cases, leave room for growth in the future.

Smart factory solutions allow you to take this a stage further by adding additional efficiencies to your processes and giving you the ability to scale and/or adapt quickly. Examples include:

- Expanding or contracting manufacturing to meet demand

- Adding new products

- Having the flexibility to change between products efficiently

Below are 11 key manufacturing / ramp strategies that will prepare your factory for the future while also driving improvements in OEE, productivity, and profitability.

1. Geographical Planning

Different geographical regions are more suited to manufacturing certain components or products than others. For example, your strategy could involve operating low-tech facilities in parts of Asia because of the large amounts of cheap labour that is available.

However, plants in Europe and other countries in the West require highly-automated solutions to be competitive. The ideal situation is to operate full production with a minimum headcount, achieving a situation that is as close to “lights out” (operator-free) as possible.

2. Build in Flexibility

The more flexibility you have in your production lines, the better. Flexibility increases the options available to your business while also making your production lines more efficient.

For example, if you plan to manufacture additional components or products in the future, you should design features now to allow your manufacturing system to accommodate this with minimal changeover disruption.

3. Build in Configurability

Configurability is linked to flexibility but takes it a stage further by allowing you to add additional process steps to your manufacturing line. This could be to meet new regulatory requirements, for example, or to offer enhanced product customisation.

4. Incorporate Robotics

Robots are integral to Industry 4.0 goals and the development of Smart Factories. In other words, they are crucial to the future of manufacturing. Your strategy should be to maximise their use through the implementation of smart factory solutions.

5. Adoption of Universal Tooling Design

Universal tooling makes it easier for your production line to adapt to multiple products as well as allowing for quick changeovers between products.

6. Late Point Configuration

Having late point configuration capabilities through a postponement strategy will increase your ability to meet customer demand for more configurable and customisable products. This is one of the most dominant modern consumer trends, so it can give you a competitive edge. You can achieve this with Factory Automation.

7. Include Full Traceability

Full traceability of products to the smallest pack size is a regulatory requirement in many countries around the world, but it also offers other benefits to your business. This includes making your business more efficient, i.e., cutting the time it takes to track and trace products from hours to seconds.

In addition, track and trace capabilities improve the level of service you offer to customers.

8. Adopt Lean and Agile Manufacturing Strategies

Being lean will enable your production lines to produce higher volumes of product, while an agile approach makes it possible to move into high mix manufacturing. Smart factory solutions make both possible.

9. Fast Time to Market Strategy

Your business cannot afford years of design and development time. Therefore, you need to streamline the process of bringing a product to market to ensure it takes as little time as possible. The best way to achieve this is through the adoption of smart factory solutions and Industry 4.0 technologies.

10. Re-Use

Digital manufacturing technologies also make it easier to re-use your production line assets to maximise usable asset life, minimise new capital expenditure, and improve ROI.

11. Horizontal and Vertical Integration

It is important you integrate smart factory solutions horizontally as well as vertically. This is because having isolated automation solution silos adds complexity, which reduces business agility and productivity.

Instead, you need to move to a point where you have fully integrated IT systems, closely linking engineering, production, marketing, and aftersales. This is sometimes referred to as closed-loop manufacturing, where product design, manufacturing, and performance are all within the same loop. This helps make your business more competitive.

In addition, you will also be able to integrate with other companies, increasing collaboration and establishing fully automated data integration networks and value chains.

Evolving Your Production Line with Smart Factory Technologies

Manufacturing has always evolved, but new technologies are increasing the pace of that evolution. Smart factory technologies and solutions, along with the 11 strategies above, will ensure your factory is equipped for the challenges and opportunities of today and the future.

Lockdown Stories: Managing the Transition with Darragh McMorrow

As with many other people across Ireland in similar positions, the early days and weeks of the Covid-19 lockdown for Darragh McMorrow involved a process of transitioning on multiple levels. Darragh is SL Controls Commercial Director.

For Darragh, the transitions involved adapting and adjusting in the workplace, at home, and personally. There were many challenges along the way, although there were successes as well.

Transitioning the Workplace

Darragh faced transitions in the workplace on three fronts:

- Adjusting to a new way of working personally

- Maintaining service levels with clients, managing the changing nature of service delivery, and pivoting the service offering towards new client priorities

- Developing and implementing new structures and processes for the wider SL Controls team to keep all business units functioning efficiently and effectively

“There were immediate challenges when news of the lockdown broke,” said Darragh. “Keith (Keith Moran – SL Controls CEO) and I worked over the weekend to put structures and strategies in place to keep our people active in all aspects of the business, particularly on client projects.

“Then, as we moved into the first week of the lockdown and the weeks beyond, the daily operational tasks involved linking in with clients – remotely – to ensure we continued to adhere to what, at the time, were rapidly changing protocols. It really was a baptism of fire at the start, but I was focused on working with customers to ensure projects continued to deliver value.

“From the perspective of our team at SL Controls, there was a very good reaction to the changed circumstances. Some people had understandable issues like childminding that we did our best to help them deal with. Generally, though, the team adapted to the lockdown quickly. The feedback on our approach was strong too.

“One of the things I think we did well from the very early part of the process was encouraging daily scrum meetings with various teams in the company. These highly focused meetings set a very clear direction of what needed to be achieved on a given day and helped us stay on target with projects.

“We even invited our customers to sit in on the scrum meetings, listening in to what was being said and planned. Customers saw this as a valuable exercise, and it validated what the SL Controls team was doing for them.

“Another thing that also helped was that we didn’t need to make any significant technology changes as we already had an excellent IT infrastructure that facilitated a seamless transition towards remote working. This included using technologies like Microsoft Teams. In fact, a few of our people ended up using their knowledge and experience to help our customers get properly set up on Teams.

“There were challenges. The working week changed more towards virtual meetings with clients, meetings which traditionally would have all been face to face. Also, I was due to spend the first two weeks of April in the US to work with our team and clients on building out our service offering in our Jacksonville office. This had to be completed virtually, which was challenging.

“However, the life sciences sector remained buoyant, and we remain as busy as ever, continuing to deliver on existing client projects while also starting new projects to meet immediate needs. Our customers viewed the lockdown period as an opportunity to take on new projects, including projects that facilitated the fact that people couldn’t be on-site, projects that could be completed remotely.

“There was also a real spirit of partnership during this period between SL Controls and our clients.”

Transitioning at Home

In some respects, the transition to working from home was smooth for Darragh. For example, he had space set aside to use as a home office, which he quickly got set up in the early days of the lockdown.

However, Darragh also saw first-hand the struggles the pandemic brought to other SME businesses in Ireland.

Darragh said: “My wife, Niamh, is self-employed and has successfully run her own beauty business for the last 10 years. In fact, she was due to have a 10-year celebration in early May.

“Like many others, she was forced to close her business in late March, and it remained closed for 16 weeks. It then opened again for 16 weeks before having to close as restrictions tightened again in the autumn.

“This meant having to temporarily let staff go while also reaching out to clients regularly to reassure them the business would reopen again. It was tough. In response to the challenges encountered having to close her business twice during 2020, Niamh invested so she could transfer aspects of the business online. This epitomises the resilience of SME owners across the country who have successfully reinvented the ways in which they can continue to reach their clients.

“From a family point of view, though, there were positives. With childminding closing down, it meant we could all spend more time together. This, coupled with excellent weather, meant we spent lots of time outside enjoying the sunshine during spring and summer, playing family games, and doing lots of arts and crafts.

“I would have to say it’s been brilliant being at home with the kids. I’m normally always on the road, travelling on a daily basis. Being at home, I’m able to do other things. Even walking my four-year-old daughter up and down to school is brilliant.”

Transitioning Personally

Being at home so much during the lockdown and with almost everything closed, many people across Ireland set themselves new goals and challenges. For Darragh, this centred on running.

“I took up running 18 months ago, starting with a few 5km and 10km races before progressing onto a few half marathons,” Darragh said. “At the beginning of 2020, I set a marker to challenge myself to run a marathon. I saw it as something to focus on and strive towards. I picked an event to run in mid-April, then Covid and the lockdown hit in March.

“So, I had to adapt the training plan. I decided to start taking part in some virtual challenges, completing different distances in a pre-defined timeframe. For example, one challenge that I completed was running five half marathons in five days.

“My daily routine during those summer mornings would be to get up at 5am, completing the run before 7am as the sun rose.

“Usually at that time of the day, I’d be in the car, so it was great to get up and get the run done. I then had the full day free for work and to spend time with the kids.

“Inevitably with Covid, three different marathon events that I signed up to take part in between April and October were postponed until 2021. But the itch was still there to try and meet my 2020 goal of running a marathon. So, I set myself a date for running a virtual marathon.

“I had a course selected in Longford and was all set for 31 October. However, two weeks before this date, Level-5 restrictions came into play, which meant I had to rethink the course.

“So, I worked out a new course within a 5km radius of my home. It meant running multiple loops of the course to reach the full marathon distance, but it was possible.

“As with my training runs, I started early in the morning, successfully completing the virtual marathon with my family meeting me for the final few hundred metres. My 4-year old daughter, Caoimhe, even helped me run the last part over the virtual finishing line.

“It wasn’t the same as running at an organised marathon event, but I achieved the goal I set at the start of the year, despite the disappointments and challenges. Now it’s roll-on 2021. I’m aiming for Longford in April… hopefully.”

Expanding Manufacturing Capacity – the Ideal Time to Implement Factory Automation Solutions

Expanding manufacturing capacity is essential to meet growing customer demand, but it also presents your business with an opportunity to take further steps towards becoming a Smart Factory.

You can even go further than this – implementing an SL Controls Smart Factory solution when expanding manufacturing capacity can improve your overall business and make the capacity expansion investment more cost-effective, whether you are expanding to meet immediate customer demand or anticipated future demand.

Let’s look at both as well as how smart factory and digital manufacturing technologies fit in, and where they can bring added benefits.

Expanding Manufacturing to Meet Immediate Customer Demand

This is usually the most urgent scenario and often requires solutions you can implement quickly. One of those options is to outsource production to another facility. This can get you over an initial surge in demand, but for a more profitable and long-term solution, the best approach is to use your existing equipment to expand capacity.

To do this, you normally only have two options available:

- Adding shifts and then either recruiting new staff or paying existing staff overtime

- Making your existing equipment more effective

The less costly of the two over the medium and long-term is making your existing equipment more effective. In fact, this is usually the best value option overall when you need to increase manufacturing capacity to meet immediate customer demand.

Other benefits of making existing equipment more effective include greater flexibility and the creation of a more scalable production line.

Smart factory solutions will expand your production capacity by improving OEE, so your equipment produces more in less time and with fewer resources.

For example, a smart factory solution can identify where the real bottlenecks are in your production line. You can then get a tailored solution targeted at that bottleneck, improving processes, increasing output, and enhancing productivity.

Expanding Manufacturing Capacity to Meet Future Customer Demand

Improving OEE can also help expand production capacity to meet future customer demand. All the above applies to this scenario as well.

What about when you plan to purchase new equipment to meet future customer demand? Where do digital manufacturing and factory automation technologies fit in this situation?

When we work on projects like this at SL Controls, one of the first things we do is to assess the digital maturity of your existing equipment to determine the integration possibilities with new equipment. This ensures you have all the information you need before selecting machines to purchase.

We then develop solutions to integrate the new equipment with the aim of automating and improving processes as well as ensuring maximum return on investment. In fact, by combining new equipment acquisition with the implementation of new smart factory solutions, you may need less equipment overall, potentially reducing the level of investment you need to make.

The Ideal Time

Expanding manufacturing capacity is a time of change in your business. It also presents opportunities beyond being able to produce more products. Those opportunities, achieved through smart factory, digital manufacturing, and factory automation technologies, will deliver long-lasting benefits to your business.

« Previous 1 … 5 6 7 8 9 … 18 Next »