Digital Transformation

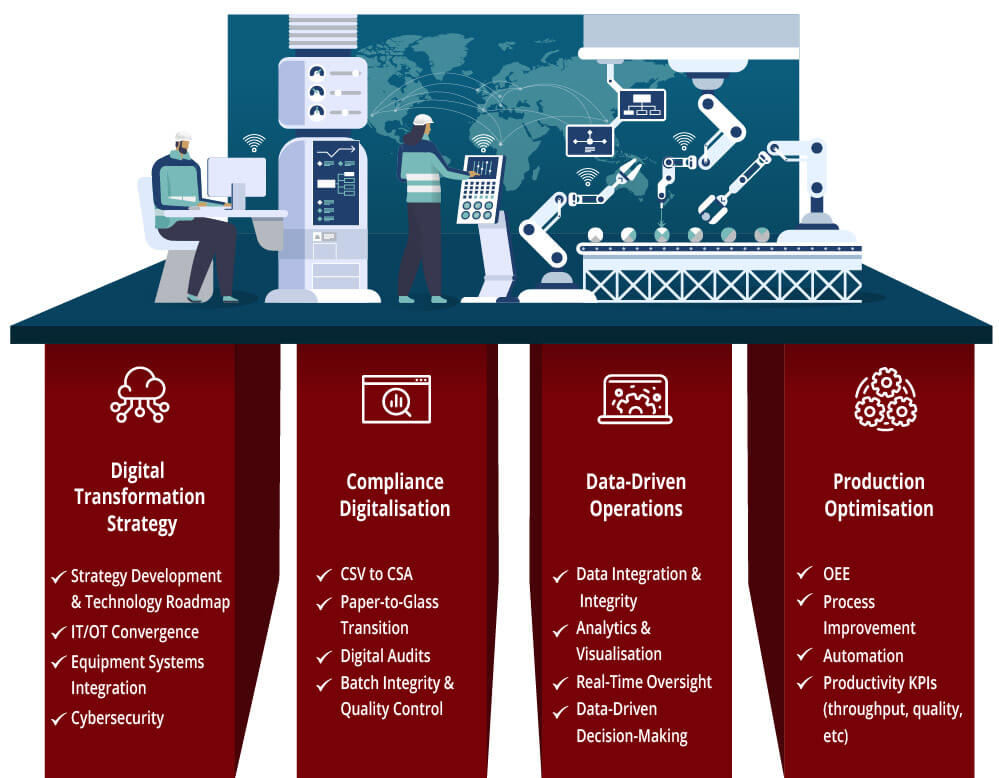

At SL Controls, we specialise in digital transformation solutions for the manufacturing sector with particular expertise working with companies in the pharmaceutical and medical device industries.

We can help you identify areas for improvement within an overall digital transformation strategy to ensure you achieve your Smart Factory objectives today and in the future. Our solutions deliver real-world benefits that maximise return on investment, with a focus on people and processes as much as technology. In relation to technology, we’ll identify, build, and customise the best solution for your requirements with a vendor-neutral approach to solution delivery.

To find out more about how our digital transformation solutions can deliver for your manufacturing facility, complete the form below or book a meeting with Frank Quinn using the calendar at the bottom of this page.

What You Can Achieve Through Digital Transformation

- Enhanced oversight and better access to data, enabling data-driven decision-making

- Improved integration of systems and equipment within the operational environment as well as in the IT space (ERP systems, CRMs, etc)

- Process optimisation, including through automation and semi-automation

- Enhanced competitiveness with more efficient operations and a stable foundation for further improvements

- Optimised quality and compliance processes

- Improved OEE, throughput, profitability, productivity, and other essential performance KPIs

Wherever you are on your digital transformation journey, we can help you decide on the next stage to ensure steady progress that delivers tangible benefits for your manufacturing operations and overall business performance.

We’ll work closely with your team to ensure there is a sense of ownership throughout the organisation, as well as to ensure new processes, technologies, and ways of working are practical and deliverable.

Our digital transformation strategy expertise includes:

- Strategy development and implementation

- Business case preparation

- Technology roadmap development

- IT/OT (operational technology) convergence

- Equipment systems integration

- Cybersecurity

Get in Touch

Compliance is essential in life sciences sector organisations, but it is also often time-consuming and costly, and it carries a significant level of risk. Traditional approaches lack transparency and are difficult to improve, but new technologies and ways of working are transforming compliance processes. Regulators are also moving towards more efficient and effective compliance practices.

It’s important your organisation modernises and digitally transforms your compliance processes to take advantage of new opportunities while reducing costs and risks. Examples include:

- Transitioning from CSV (computer systems validation) to CSA (computer software assurance)

- Paper-to-glass transitions in CAPA and other essential quality and compliance processes

- Digital audits

- The digitalisation and automation of batch integrity and quality control

At SL Controls, we can help unlock the power of data in your manufacturing operations to optimise processes, drive efficiency savings, deliver productivity improvements, and enable data-driven decision-making. We can develop and implement solutions that integrate the equipment, systems, and platforms that are essential to your operations, including legacy systems/equipment, new technologies, and everything in between.

The projects we deliver will increase automation in your manufacturing operations, improve product quality, enhance transparency, and enable more effective use of your resources. You will also have a solid data foundation to build on for the future, driving further operational improvements in your facility.

What do you want to achieve:

- Data integration across systems, platforms, and equipment

- Robust data integrity protocols, solutions, and practices

- Actionable data analytics, dashboards, and visualisations

- Real-time oversight

- Data-driven decision-making

Digital transformation technologies and solutions can optimise your operations, enabling you to produce more with less. We can help you achieve improvements in throughput, product quality, compliance, batch changeovers, supply chain management, and enterprise system integrations.

From greenfield sites to adding new production lines to upgrading existing facilities, we have the expertise to deliver real-world benefits for your operations. We focus on people, processes, and technologies with an emphasis on business outcomes and building for the future as you continue your digital transformation journey.

The objectives you can achieve include:

- OEE improvements

- Process improvements, including eliminating errors

- Automation, especially of time-consuming, repetitive, and non-value-adding tasks

- Improvements in essential operational and business KPIs, including throughput, quality, and profitability

Digital transformation will enhance your competitiveness, improve compliance, and drive future success for your manufacturing facility. Send us a query or use the calendar below to book a Teams meeting with Frank Quinn.