Our Services

Systems Integration

Bespoke, cost-effective, and forward-thinking Equipment Systems Integration solutions that improve OEE, enhance productivity, automate business & manufacturing processes, ensure compliance, and more.

More InfoSmart Factory

Improving your manufacturing facilities, business processes, and supply chain efficiency with innovative Industry 4.0 solutions that reduce business risk, improve productivity, and create new opportunities.

More InfoValidation

Assessments of existing validation processes, as well as developing and implementing new validation solutions. Our expertise includes software, process, equipment, and test method validation.

More InfoProject Management

We deliver successful projects that meet business objectives throughout the full project lifecycle, with particular experience managing projects for companies in the life sciences and technology sectors.

More InfoProfessional Placement

Boosting your team for the long or short-term, we've got the skills and experience in regulated, high-volume manufacturing environments that your business needs. Customised solutions with fast turnaround.

More InfoSmart Manufacturing Consultancy

Innovative solutions in areas like Industry 4.0, digital maturity assessments, critical decision support, process optimisation, QMS development, implementation of CSA techniques, standards development, and more.

More InfoSupport Desk

Tailored, ITIL-compliant, and secure support services delivered remotely and on-site. We have the expertise available when you need it to minimise production delays and disruptions to output.

More InfoThe SL Controls Difference

Customised Approach

We will develop a solution tailored to your production line, business objectives and future plans.

Innovation at Our Core

We work with cutting-edge Industry 4.0 technologies to ensure your business can benefit from new opportunities.

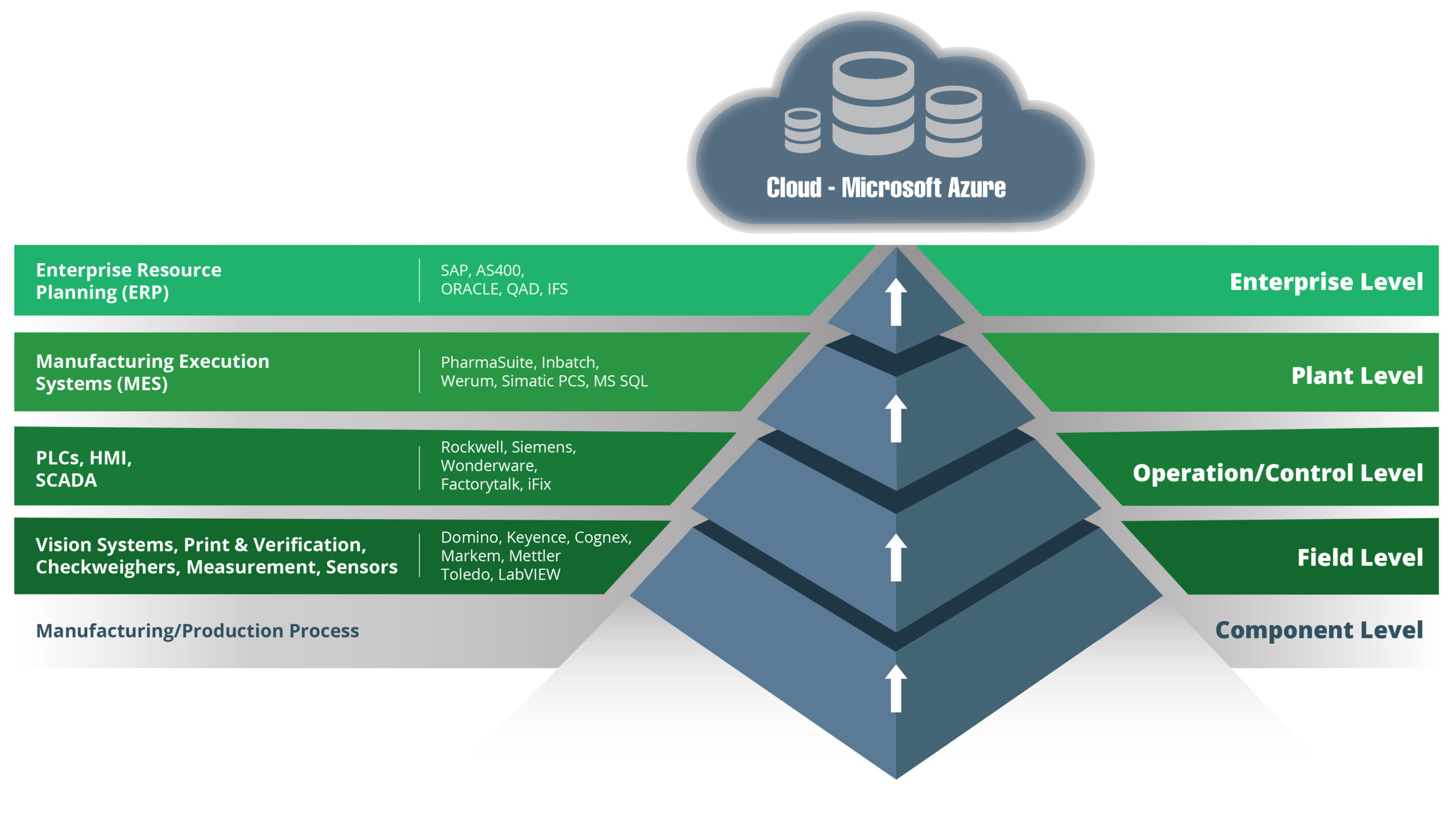

Software Expertise

Our team has broad knowledge and expertise across a wide range of technologies, platforms, and systems. This includes everything from ERP systems to manufacturing execution systems to PLCs to sensors. Why is this important? Whatever equipment, systems, or platforms you currently use, whatever solution you want to implement, and whatever objective you want to achieve, we can deliver.

Clients We Work With

Building Partnerships

At SL Controls, we work with some of the largest companies in the pharmaceutical, medical device, and technology industries, delivering solutions in Ireland, Europe, the US, and around the world.

Delivering Today to Shape the Potential of Tomorrow

About Us

At SL Controls, we deliver industry-leading Smart Manufacturing and systems integration solutions to the Life Sciences and Technologies sectors.

Through our technical expertise, we can optimise your manufacturing processes to meet your global supply demands while also delivering efficiency gains and productivity improvements.

Success Stories

Performance Monitoring of Databases

Performance Monitoring of Databases

Our customer had a bespoke part tracking database designed to move data between machines in its production facility. What would the impact of 50-plus new machines have on this database? How would the customer verify the database could effectively and accurately scale up to this increased level? Find out how we answered these questions by developing a bespoke database performance monitoring solution.

Read More

25% Output Increase, Zero Additional Resources

25% Output Increase, Zero Additional Resources

In this project, we helped our customer increase their manufacturing capacity without having to scale up resources. The customer operates a high-volume manufacturing facility and was forecasting increased demand. The business wanted a solution that would enable this scaled-up production capacity when it was needed, but with additional requirements, including cost avoidance. Find out how we delivered.

Read More

50% Output Increase & New Product Introduction

50% Output Increase & New Product Introduction

At SL Controls, we often work on projects where the scope is broad and can contain many different elements. This Success Story is one example. The main element of the project was to add an auxiliary production line so the customer could increase capacity. The facility was also introducing a new product, plus the customer wanted to update some of its manufacturing technologies. Learn more about what we did.

Read More

Thinking Ahead – Our Blog

POMSnet MES Integration Capabilities – A Brief Guide

Integration is one of the primary considerations when choosing a Manufacturing Execution System (MES) for your pharmaceutical […]

Read MoreHow Ignition Can Enable Your Manufacturing Facility’s Unified Namespace (UNS) Journey

The benefits of a UNS structure are hard to ignore (for an explanation of UNS and how […]

Read MoreBest Practices for Security in the Unified Namespace (UNS)

The Unified Namespace (UNS) is increasingly viewed as a critical architecture approach in manufacturing environments as it […]

Read MoreAccreditations & Affiliations

Sign up to the SL Controls newsletter for updates and news about the industry's latest developments