OEE – Overall Equipment Effectiveness – has long been a performance measurement used in factories to reduce costs, improve quality, increase capacity, and more. The objective is always to optimise OEE. How can Smart Factory technologies help with this optimisation?

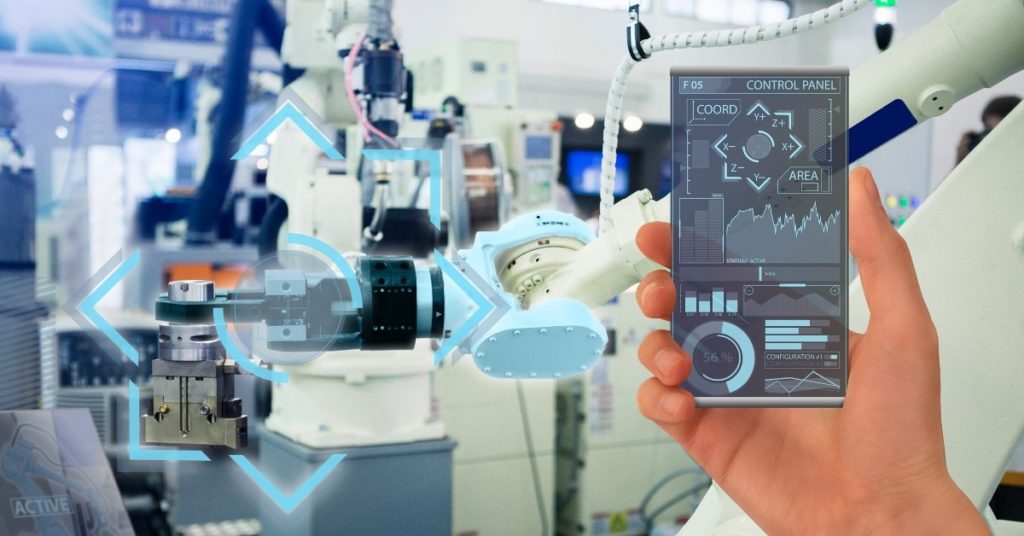

Let’s first quickly define the Smart Factory. It’s a complex picture but, at its simplest, smart factory solutions turn production lines into data-driven production lines. This use of data improves performance, enhances decision-making processes, and makes it possible to increase levels of automation.

Production line controls are also enhanced, factories become more flexible and adaptable, and customer service levels are improved.

Why OEE is Important

OEE typically looks at three key main factors: availability, performance, and quality.

- Availability – the time a line or machine is available for production

- Performance – the speed at which the machine or line is performing compared to its optimum speed

- Quality – taking into account defective products and their impact on performance

All three together give an OEE result. Perfect conditions would give an OEE result of 100 percent. This would be a situation where the line and all machines are always available, everything runs as fast as it possibly can, and every product produced is perfect.

Of course, these perfect conditions don’t exist in the real world. After all, components fail, machines need to be serviced, machines can break down, and multiple factors can impact product quality.

The aim, therefore, is to optimise OEE and continuously make improvements.

How to Optimise OEE

Sometimes there are obvious improvements that can be made to optimise OEE. Generally, however, decisions on actions to improve OEE need to be based on data from the line itself.

In other words, collecting data from the production line and from individual machines, processing that data, analysing the data, and then making a decision on where the best OEE improvements can be made.

This is where Smart Factory technologies become so important as a central component of most Smart Factory solutions is the sensor.

In relation to OEE, sensors on machines collect data and transmit it to a central location where it is processed and analysed. That analysis can be manual but smart factory technologies also make it possible for automated data analysis and automated decision-making.

This makes OEE optimisation a real-time process as well as a process that responds to situations that have already occurred. Overall, it speeds up the time it takes to deal with problems that impact OEE.

In addition, smart factory solutions are capable of effectively processing far greater amounts of data than manual systems. This makes it possible to identify problems and patterns that only become obvious when analysed using a large dataset over time.

Practical Examples of Smart Factory Technologies Improving OEE

- Availability – sensors monitoring equipment alongside machine learning algorithms can predict equipment and component failure before it occurs. This enables the scheduling of maintenance at the most efficient time while also helping to eliminate the worst influencing factor on availability: unplanned downtime.

- Performance – the predictive maintenance example above applies to performance also as predictive maintenance ensures machines and lines not only run but are optimised for performance. Digital twin and other modelling solutions can also be beneficial. These technologies allow engineers, with the help of artificial intelligence and machine learning, to test different scenarios and how they would impact OEE without any risk to real-time production.

- Quality – in addition to identifying actual and potential faults, sensors on machines and equipment can also identify variations in production lines that impact quality. This includes things like temperature, dimensions, tolerance levels, etc. Remedial or corrective actions can then be taken.

Smart Factory Benefits

Improving OEE is only one of the benefits that Smart Factory technologies offer. That said, given the importance of OEE to overall performance and business profitability, the benefits in relation to OEE optimisation are significant.