Equipment Systems Integration

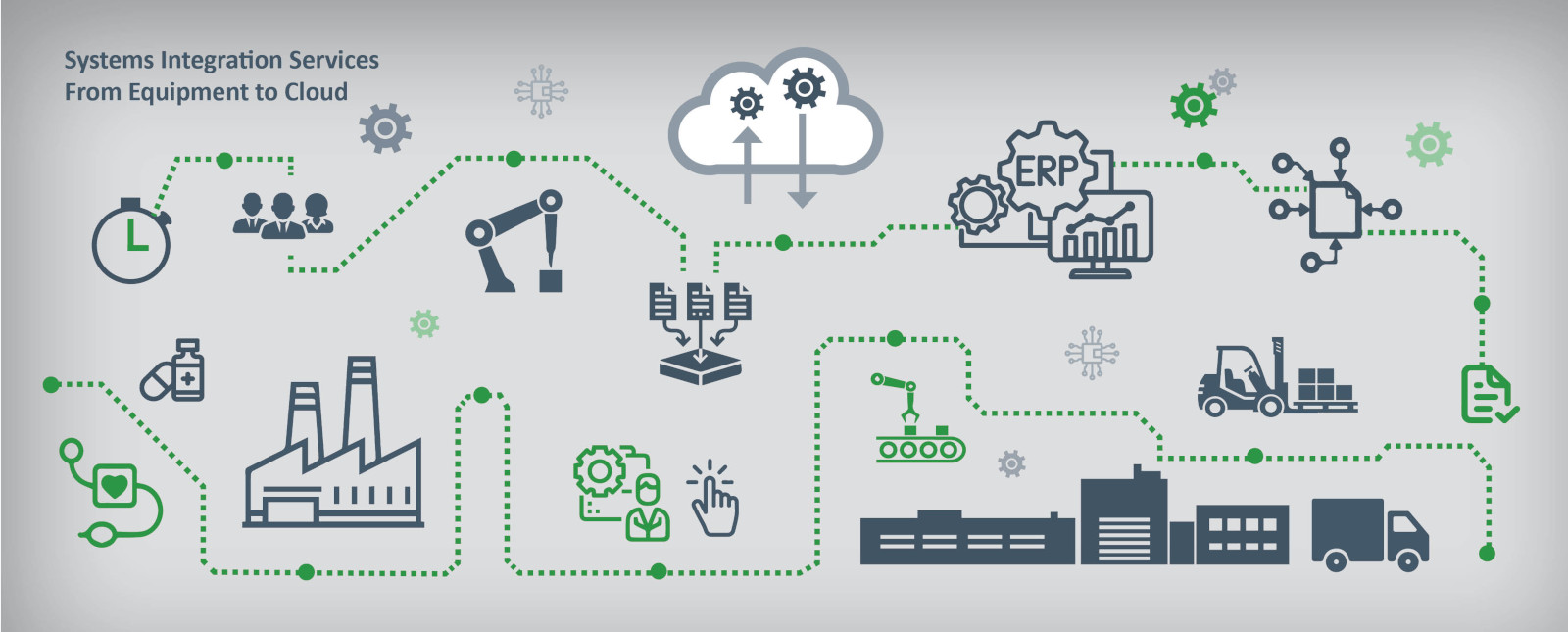

At SL Controls, we provide a full range of Equipment Systems Integration solutions with tried and tested processes that are completely vendor-neutral.

Our experience includes developing, programming, and validating automation solutions that will help you meet your compliance objectives, enhance OEE, improve productivity, and reduce manufacturing costs. In addition, our Equipment Systems Integration solutions are bespoke, cost-effective, and will deliver maximum return on investment.

If you are looking for a solutions provider who understands the Equipment Systems Integration needs of your business, email [email protected] or complete the form and we’ll get back to you.

Why Choose SL Controls for Systems Integration

At SL Controls, we specialise in the delivery of Equipment Systems Integration solutions. We have extensive experience working with manufacturers in high-volume, highly regulated industries, including pharma and MedTech.

- We provide bespoke solutions tailored to the needs of your business.

- We develop innovative solutions for challenging situations.

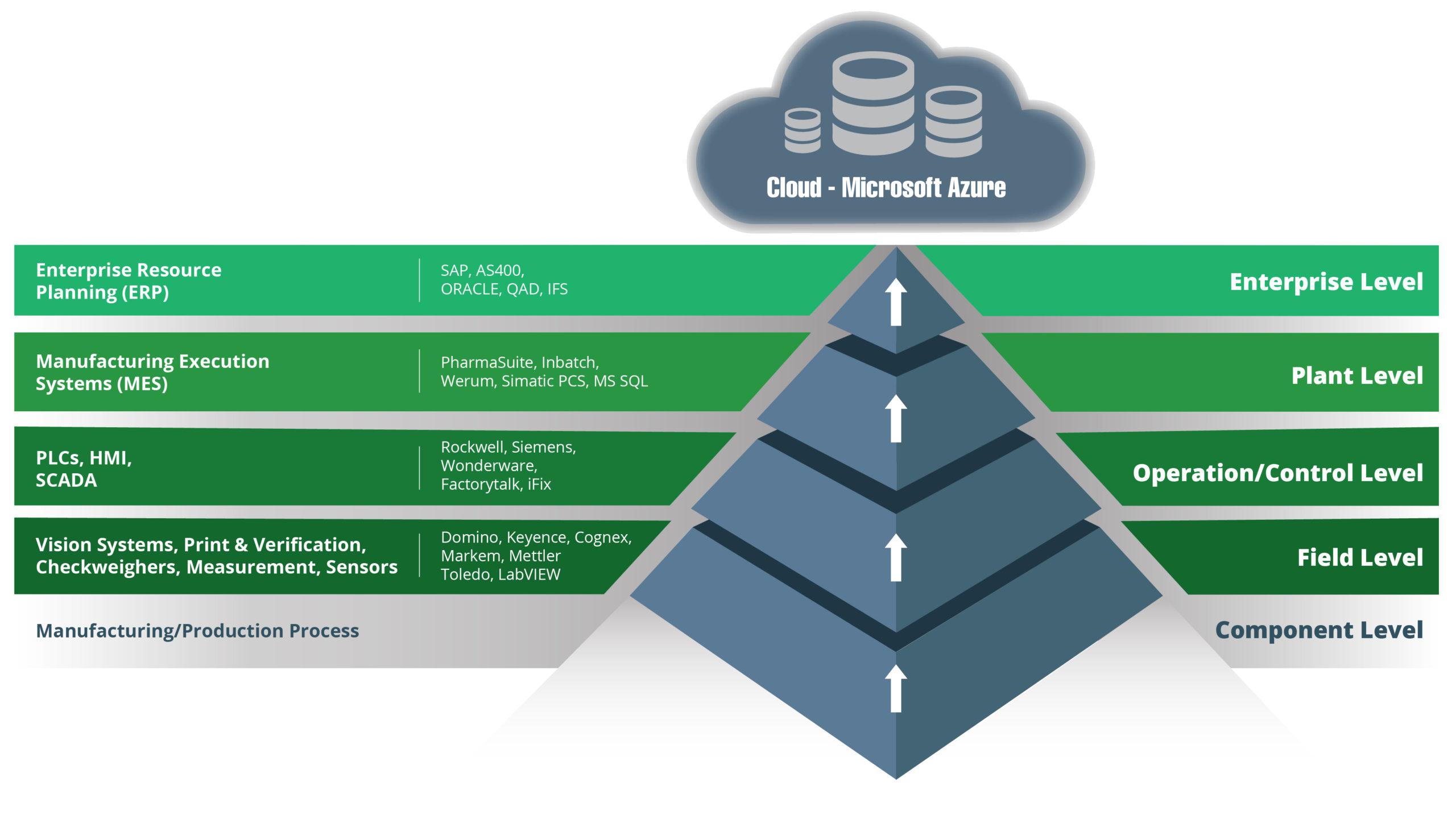

- We have extensive expertise as well as knowledge of a variety of platforms.

We have developed extensive software capabilities at SL Controls, ensuring we can deliver a solution that meets your requirements, whatever systems and platforms you currently use. View our Software Stack to find out more about our software capabilities.

- Creating line clearance interlocks and product changeover controls for batch management.

- Interacting with and controlling all printer details, vision verification systems, batch parameters, and machine recipe changeovers.

- Performing all data logging for process parameter and OEE calculations.

Our software development team is experienced in the design and implementation of bespoke, validated applications within regulated environments. These unique solutions will enhance your manufacturing facility with automated manufacturing, testing, logging, reporting, and visualisation features.

- NI LabVIEW, VB .Net, SQL, C++

- Wonderware, Cimplicity, Zenon

- Allen Bradley, Siemens, CODESYS, Elau

We can provide you with an efficient and professional support service through an ITIL-compliant service desk. We use a web-based platform that lets you submit support tickets 24/7, and we’ll tailor our SLA according to your requirements. We offer on-site support as well as compliant and secure remote support.

- A web-based platform so your team can log customer support tickets and service requests 24-hours a day, seven days a week.

- Your Service Level Agreement will be completely tailored to meet your requirements and budget.

- Both on-site support and support provided with remote technologies.

A properly designed manufacturing network is critical to capacity, reliability, redundancy, and equipment optimisation. At SL Controls, we are specialists in developing and implementing software solutions that continuously improve manufacturing and business processes, from productivity to OEE to decision-making effectiveness.

- OEE improvements and robotic process automation.

- Horizontal integration, vertical integration, and external integration.

- Improved use of data to enhance decision-making and for predictive analytics.

Our Line Clearance and Batch Execution Systems ensure secure, auditable, and rapid product changeovers. We manage interactions in partnership with your team by creating line clearance interlocks and product changeover controls, data logging, controlling printers, vision verification systems, batch parameters, and machine recipe changeovers.

- Creating line clearance interlocks and product changeover controls for batch management

- Interacting with and controlling all printer details, vision verification systems, batch parameters, and machine recipe changeovers

- Performing all data logging for process parameter and OEE calculations

We can provide vendor-independent support to ensure you acquire the right technology for your manufacturing requirements. Our line-specific, comprehensive, and holistic design plan will deliver a range of benefits, including reduced costs, maximised Overall Systems Effectiveness (OSE), and projects that are completed on time and within budget.

- Reduce costs.

- Maximise Overall Systems Effectiveness (OSE).

- Complete projects on time and within budget.

Download our Equipment Systems Integration case study to get an understanding of the practical solutions we have delivered.

Download Case StudySpeak to a member of our team to find more about how our Equipment Systems Integration solutions can help your manufacturing operations. Email [email protected] or complete the form and we’ll get back to you.