Delivering Your Smart Factory

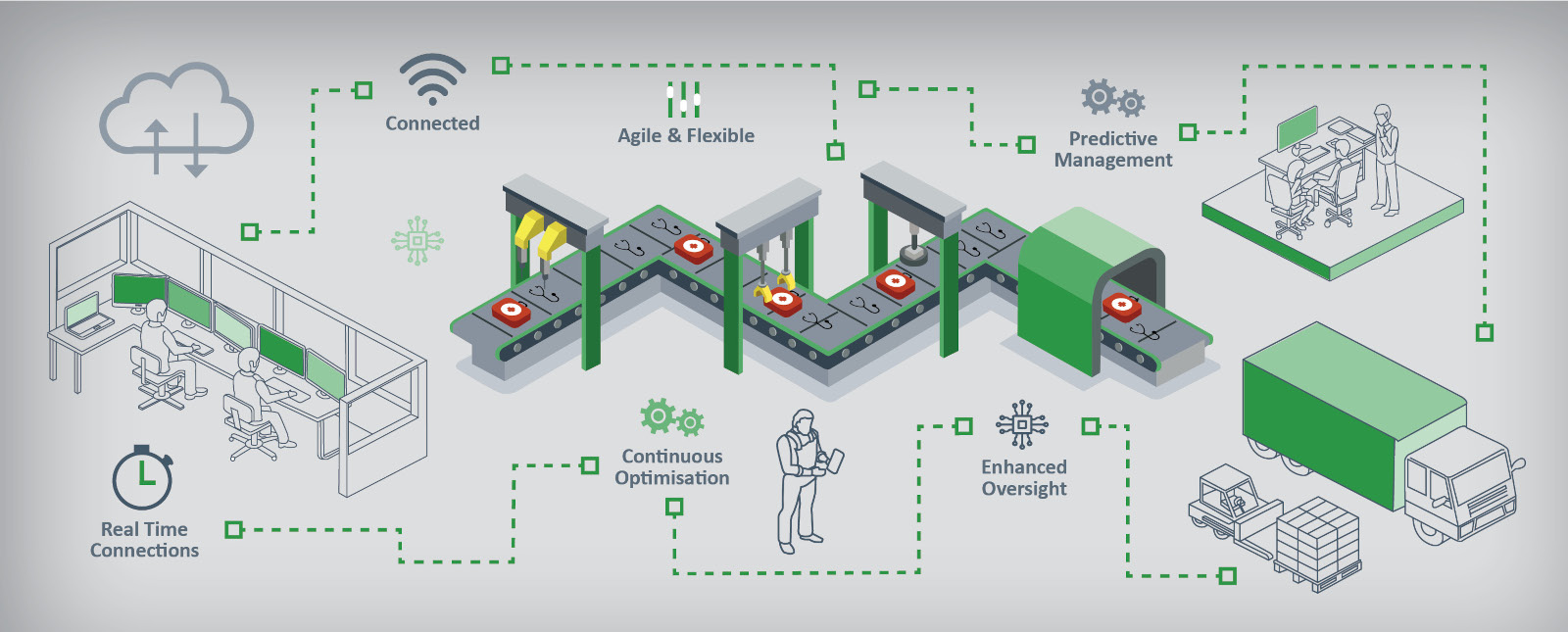

The Smart Factory is the future of the manufacturing sector. With the right solutions in place, your operation will become more efficient, OEE will improve, and productivity levels will increase. You will also be able to identify and implement new business opportunities.

At SL Controls, we can help you on your Smart Factory journey, wherever you are starting from.

SL Controls is now NNIT. Find out more about NNIT’s Smart Factory solutions.

Let us help you progress your Industry 4.0 journey by delivering a bespoke Smart Factory solution for your business. Please contact us to find out more by emailing [email protected] or completing the form.

Future-Proofing Your Business with Smart Factory Solutions

Manufacturing is going through a process of transformation in all industries and sectors, including pharma, medical devices, and technologies. This transformation will improve productivity in your business, automate processes, and deliver efficiency savings. Our Smart Manufacturing expertise includes:

- Industry 4.0 and future factory services.

- Capital programmes and end-to-end project management of production line acquisition.

- Key resource placement.

- Automation strategy as well as equipment relocation, design, and consultation service.

Industry 4.0 involves the digitalization of your manufacturing and business processes. The Smart Factory is a central component of this and, for most businesses, is the logical next step towards Industry 4.0.

- Automation strategy development and technology road-mapping.

- Digital maturity assessment, business case development, and solution delivery.

- Equipment system integration (using DiVOM) and OSE calculations for production systems.

Modern manufacturing environments need access to relevant data to improve oversight and decision-making. Your data should also be working for your business through technologies like artificial intelligence (AI), predictive analytics, and machine learning to automatically improve performance, efficiency, and productivity.

At SL Controls, we can deliver a manufacturing data analytics solution that will deliver on your requirements. We specialise in using Microsoft applications and platforms that offer enterprise-level performance and that integrate with the Microsoft apps you currently use.

Get in Touch

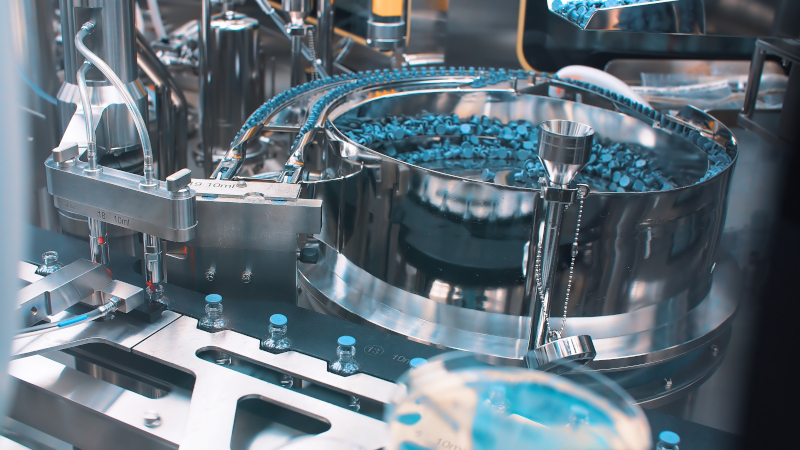

Line clearance and batch management/changeover processes on your production line can have a significant impact on productivity and output. They also influence quality control as well as your track and trace processes. As a result, improving line clearance and batch management is essential in your Smart Factory.

At SL Controls, we develop and implement advanced, future-proof batch execution systems and line clearance solutions to ensure the rapid, secure, and fully transparent changeover of products on your lines.

We can integrate our solutions with your ERP and MES systems, and they are fully 21 CFR Part 11 compliant.

Get in Touch

Moving your IT infrastructure to the cloud will deliver significant benefits for your business, including reducing IT capital expenditure and making your infrastructure more agile, flexible, and future-proof. At SL Controls, we have expertise in the delivery of cloud connectivity and integration solutions, particularly using the Microsoft Azure cloud platform.

- Experience delivering cloud migration and integration solutions for companies in regulated industries, including pharma and MedTech.

- In-depth knowledge of Microsoft apps and platforms as well as MES and ERP platforms.

- We’ll deliver a bespoke solution that will meet your requirements.

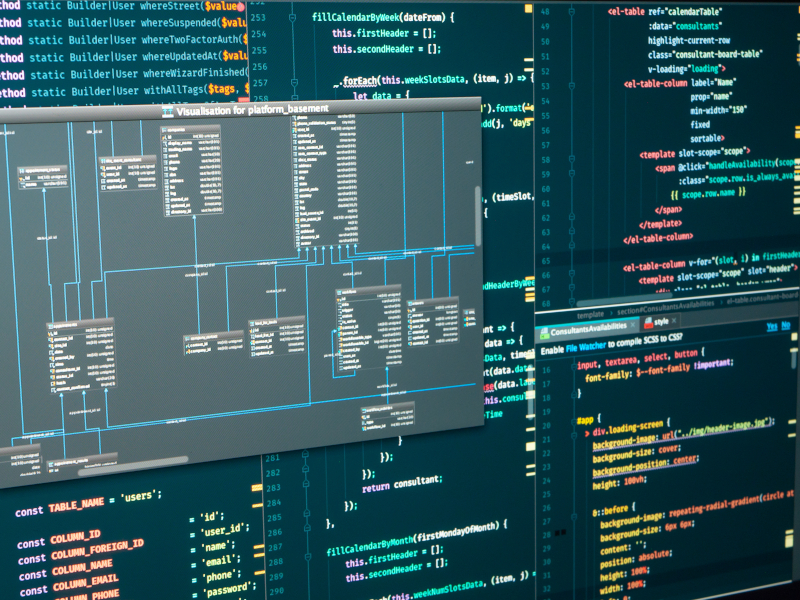

There is a lot of data that is potentially available in your facility that, when put to work, can improve productivity, efficiency, oversight, and quality. Data comes in various forms, however. It will be produced from a range of sources, from legacy systems to the newest platforms, and it will have different levels of importance depending on the application.

At SL Controls, we have experience handling big data applications and multiple data streams, making sense of the data in your system. We do this using advanced techniques and architectures that enhance your production facility’s performance and how you use data.

Get in Touch

It is an old saying, but “rubbish in, rubbish out” is as true today as it has ever been. At SL Controls, we make sure the data being used in your systems is accurate and consistent across its full lifecycle.

We’ll also make sure you have the customised dashboards and reports that you need for full, real-time oversight of your operations. Having access to accurate, usable data will also improve decision-making in your organisation.

Get in Touch

Databases are an essential part of most modern manufacturing facilities, including for tracking parts on a production line. For example, databases enable machines to produce lots independently, delivering significant productivity gains.

However, what happens if you want to scale your operations, adding new machines, equipment, or lines? Is your database capable of the additional workload?

At SL Controls, we have experience developing, testing, and implementing database scaling solutions as well as solutions that enable capacity testing of your database before you purchase any new equipment and before you implement changes on your production line. This capacity testing capability will give you confidence that your database can perform when you scale up production.

Get in Touch

SL Controls will deliver a bespoke Smart Factory solution on your production lines that will improve your business today and prepare it for the future.

Our Smart Factory team has extensive experience, plus we have the skills and resources to deliver an end-to-end solution. This reduces your costs and makes the overall process smoother.

The Smart Factory process we use is well-tried and tested, and we are continuously innovating and improving. As a result, it will deliver on your business objectives.

Get in Touch

At SL Controls, we deliver Smart Factory solutions that focus on the objectives of your business. This means we don’t simply concentrate on the technical aspects of the project.

Instead, we get a holistic view of your overall manufacturing process and how it functions with other business units within your organisation. We’ll then design and develop a Smart Factory solution around this understanding.

Get in Touch

Our case studies will give you a better understanding of the skills and expertise we have. They will also give you an indication of the benefits we can bring to our business.

Case study 1 – Industry 4.0

Case study 2 – High Volume Manufacturing Line Relocation

Case study 3 – Manufacturing Capacity Expansion

Case study 4 – NPI High Volume Manufacturing Line Design & Acquisition

Case study 5 – NPI Flexible Proto Line Development

Get in TouchSpeak to a member of our Smart Factory team today to find out more about what we can offer your business. Please complete the form or email us at [email protected] and we will get back to you.