Risks can enter an automation project at just about any stage. Those risks can result in serious consequences from budget and schedule overruns to unplanned downtime, disrupted supply chains, and more.

Therefore, it’s important to de-risk your automation project at every possible stage. This ensures errors are reduced to a minimum, as well as ensuring the project delivers on expectations.

We have a project delivery process at SL Controls that helps to reduce risks in all project phases. There are also factors relating to your organisation and operations that need to be considered. We’ll start with those.

Minimising Risks In Automation Projects – What You Can Do

There are five crucial areas you should look at to minimise risks in your automation project:

- Set clear goals – you should have a clear understanding of why you are embarking on the automation project and what you want to achieve. What are the objectives, what has to happen to meet those objectives, and how will you measure success?

- Senior leadership buy-in – getting senior leadership buy-in at the earliest possible stage will make the process smoother, as well as reducing risks.

- Resistance to change – are there people in the organisation who will resist the change that automation will bring? This situation is not unusual. The key is to ensure you have a well-thought-through plan of how you will deal with this resistance. Examples of things you can do include communicating effectively, addressing fears head-on, and offering training.

- Resources and expertise – what resources and expertise will you need for the successful delivery of the automation project? If you are not completely sure of the expertise that will be required, how will you get that information? What level of resources do you have in-house? What are the key skills and capabilities you will need from a third-party provider?

- Stakeholder communication – communication is a potential risk factor in automation projects as communication failures can lead to errors, delays, overruns, and other problems. Therefore, you need to develop an effective communication strategy that includes all stakeholders.

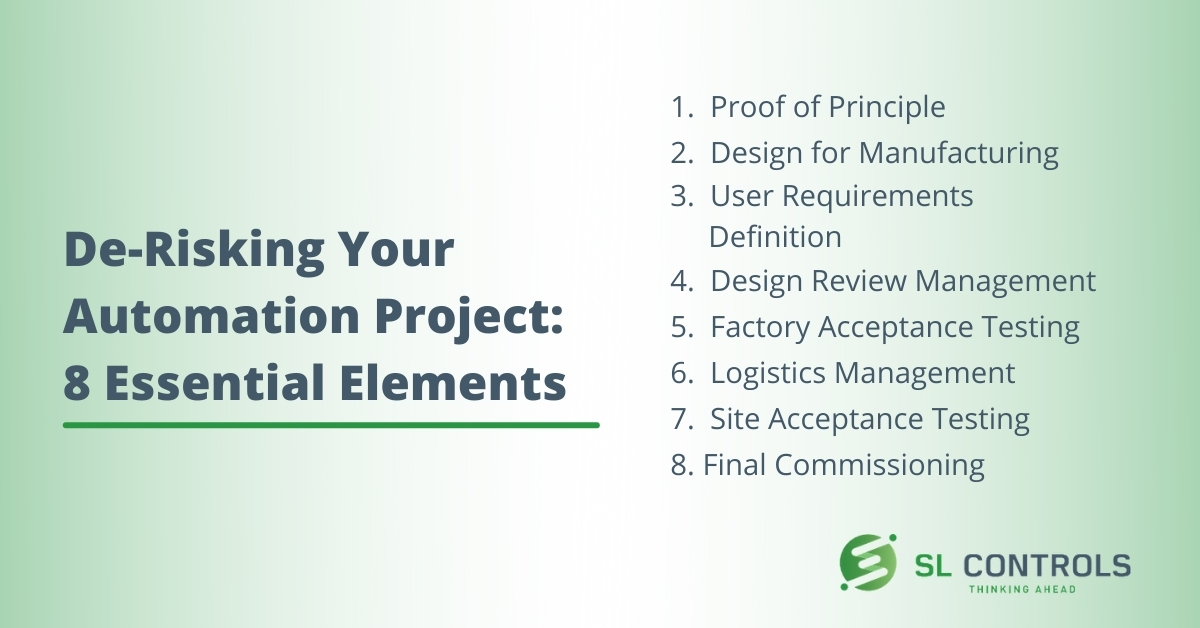

De-Risking Your Automation Project At Every Stage Of Delivery

At SL Controls, our project delivery processes focus on de-risking at every stage, from the pre-automation phase through to final commissioning and testing.

Central to this are eight essential elements to de-risking all automation projects.

1. Proof Of Principle

Proof of Principle (POP) involves proving the feasibility of achieving the desired outcomes for the project based on things like the technologies currently available, budget constraints, timelines, etc.

By going through the POP process, we can avoid pursuing goals or targets that are not feasible or achievable and, instead, make changes to achieve the desired outcome. This prevents wasted expenditure.

2. Design For Manufacturing

Design for manufacturing (DFM) is most commonly used when designing new products. It involves ensuring the design of a product makes it easy to manufacture within the cost target.

In relation to automation projects, we adapt DFM principles to ensure we don’t just create a fancy automation solution. Instead, our goal is to develop an automation solution that is reliable, and that improves several key metrics, i.e., OEE, output rate, quality, productivity, etc.

3. User Requirements Definition

A User Requirements Definition is a document we create that specifies what you, as our client, expect the automation project to deliver. It’s not a technical document but should include, among other things:

- Required functions and features of the solution

- Workflow of the solution

- Integration requirements

- Data requirements

- Regulatory requirements

- Life cycle requirements

In terms of the de-risking process, creating and agreeing on a User Requirements Definition is part of the project’s feasibility analysis. It also ensures everyone is on the same page.

4. Design Review Management

The design review is an essential part of de-risking automation projects. In regulated sectors, it’s also a compulsory part of the process and must be properly documented.

A design review tests and evaluates the design of the automation solution against the User Requirements Definition.

5. Factory Acceptance Testing

The goal of Factory Acceptance Testing (FAT) is to ensure the equipment, platforms, and components of the automation solution can deliver on requirements. It is a process that can highlight issues and errors, so it plays a key role in de-risking automation projects.

6. Logistics Management

Logistics management is often taken for granted in automation projects, despite the fact there are so many things that can go wrong, many of which can have significant consequences. A good example is a piece of equipment getting dropped and damaged. This could set a project back for weeks or months.

To mitigate these risks, we insist on using qualified and approved freight forwarders who take essential steps to ensure the smooth teardown, crating, and transportation of equipment and machinery. This includes:

- Mapping every aspect of the route

- Planning the equipment required

- Deciding on the crate specification

- Selecting appropriate bracing to secure equipment

- And more

7. Site Acceptance Testing

While the aim of a de-risking strategy is to eliminate risks at the earliest possible stages of an automation project, the Site Acceptance Testing stage is still important. It’s also an essential GMP requirement.

8. Final Commissioning

De-risking in the final commissioning phase includes IQ (installation qualification), OQ (operational qualification), and PQ (performance qualification).

De-Risking Strategy

By emphasizing de-risking in the earliest stages and then focusing on the elimination of risks through each subsequent stage, we ensure the successful and smooth delivery of automation projects, maximising your ROI.

Comments are closed.