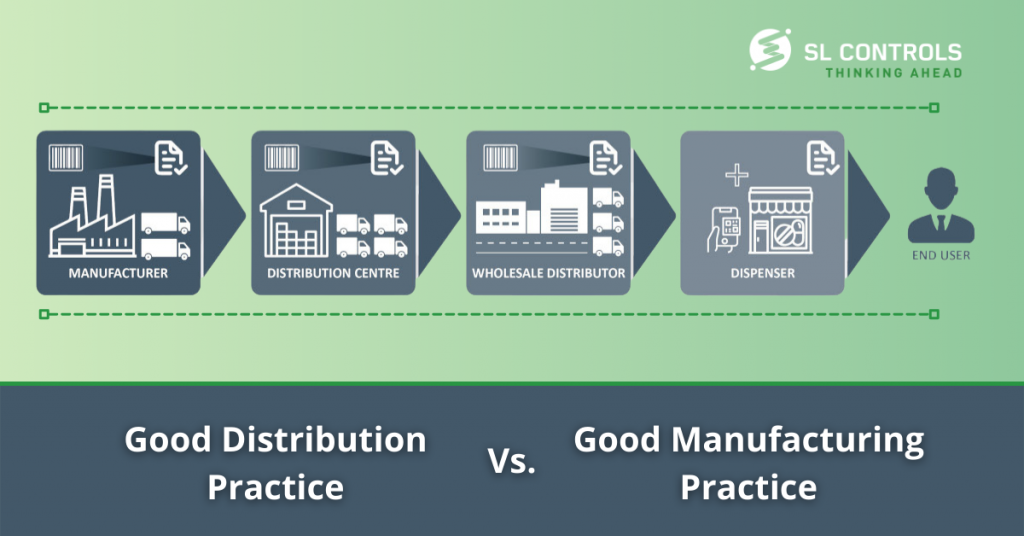

Good distribution practice (GDP) and good manufacturing practice (GMP) are quality standards and guidelines that have the same ultimate objective – to ensure medical device and pharmaceutical products are safe, meet their intended use, and comply with regulations.

GMP focuses on manufacturing processes, while GDP covers distribution activities. There are crossovers between both manufacturing and distribution, however. So, what are the main differences between GDP and GMP?

Definitions

To understand the key differences and how they impact operations, let’s first look at the definitions of GMP and GDP.

What is Good Manufacturing Practice?

Good manufacturing practice involves consistently producing products that meet quality standards. This requires the implementation of a system where the aim is to minimise risks, from incorrect labelling of products to contamination to incorrect ingredients and everything in between. GMP systems cover all parts of the production process, from raw materials through to the production of the finished product.

What is Good Distribution Practice?

Good distribution practice involves maintaining the quality and integrity of products through all stages of the supply chain. It sets out minimum standards to ensure medical device and pharmaceutical products comply with regulations. GDP applies to warehousing, storage, and transportation, and it covers everything from storing and transporting products under the right conditions. Doing so, minimises the risk of product degradation, ensuring product integrity at the correct destination on time.

Unique Aspects of GDP

There are parts of GDP that are unique, so they don’t apply to GMP guidance and standards. Those unique parts of GDP include guidance on transportation covering aspects such as temperature control, vehicle controls, and conducting risk assessments on transport routes. Guidance on brokers is also unique to GDP, i.e., guidance on those who facilitate transactions in the supply chain without ever handling the product.

Areas of Minimal Difference

While there are sections of guidance that are unique to GDP, there are also areas where there is minimal, if any, difference between GDP and GMP. These include:

- Quality management – both focus on ensuring members of staff are properly trained, and the facilities and equipment are fit for purpose. Management review meetings also feature in both, albeit with a bit more emphasis in GDP.

- Outsourced activities – minimal difference.

- Self-inspections – minimal difference.

- Complaints and returns – there are more details in GDP covering the control and management of product returns. Otherwise, there is minimal difference between the two standards.

Main Differences Between GDP and GMP

Aside from the unique aspects of GDP compared to GMP, the differences fall under four main headings:

- Personnel

- Equipment and premises

- Documentation

- Operations

Personnel

GMP talks about the role of Qualified Person while the focus of GDP is the role of Responsible Person. This isn’t just a difference in words, though, as a Responsible Person has different responsibilities under the guidance. They can’t, for example, certify the release of a product batch, whereas a Qualified Person can.

Equipment and Premises

The main difference between GDP and GMP is the additional controls included in GDP to cover products and materials that are either radioactive or highly sought-after on the black market.

There can be blurred lines in this area, though. Take the thermal mapping of storage areas as an example. Many facilities working to remain in compliance with GMP will have thermal mapping systems in place, even though they are not specifically required by GMP. However, thermal mapping is a requirement under GDP.

GDP also puts more emphasis on instrument calibration, particularly those instruments involved in product traceability processes.

Documentation

As might be expected, there is a reduced requirement in GDP for manufacturing and testing documentation, but an increased requirement for storage and personnel documentation.

Operations

In GMP, these guidelines are covered under production, so the heading is different. In terms of the more practical specifics, GDP places more emphasis on fake product identification, supplier and customer approval, and exporting processes.

Not Just About Regulatory Compliance

Both GDP and GMP are important components for maintaining regulatory compliance when selling medical device and pharmaceutical products. The standards also have other benefits to businesses involved in these processes, including manufacturers as well as those further down the supply chain.

This includes helping to reduce the prevalence of fake medicines, improving the quality of products produced and delivered to patients/clinicians/customers, and minimising business risk in the manufacture and distribution of healthcare products.