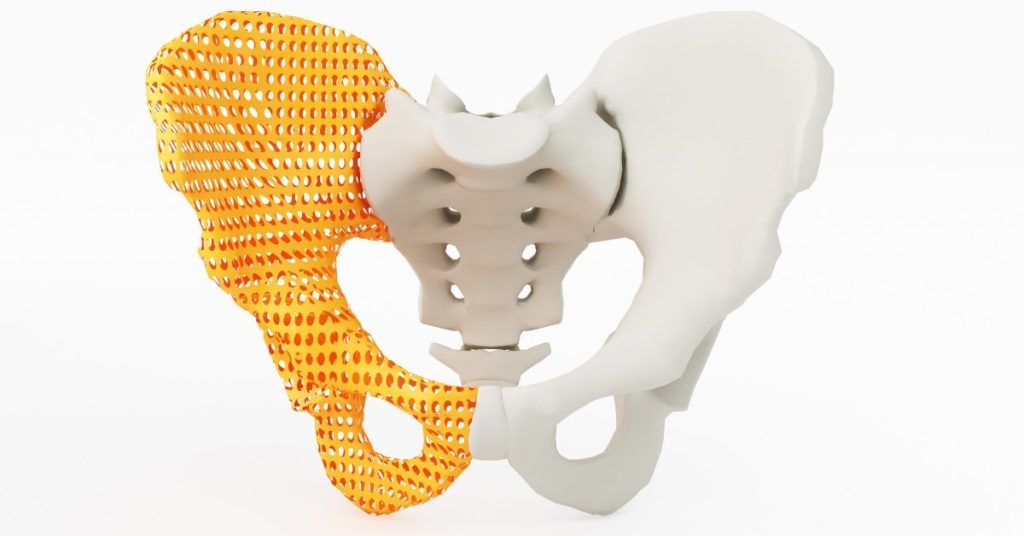

One of the growing trends in the medical device industry is customised products for individual patients. An example is an implant designed specifically for an individual patient. A range of technologies make products like this possible, including new additive manufacturing technologies.

Furthermore, customised medical device products offer significant benefits to patients. There are benefits to the MedTech industry too, although customisation also presents challenges.

For medical device manufacturers, product customisation requires a change of strategy, manufacturing processes, and business processes. There are also challenges in terms of regulations.

How do you get regulatory approval for a customised medical device product?

Understanding the Definition of Custom-Made

The starting point is to understand the definition of what EU regulators regard as a custom-made product. Crucially, this definition is changing with the introduction of the new EU Medical Device Regulations (MDR).

Previously, a medical device produced using an additive manufacturing technique (often referred to as 3D printing) and customised for a specific patient would have been considered a custom-made product.

This is no longer the case with the new EU MDR.

A New Definition for Custom-Made Medical Devices in the EU

So, what do the new regulations say in their provision for custom-made medical device products?

In MDR 2017/745, a custom-made product is defined as a medical device that has “specific design characteristics” that makes it suitable “for the sole use of a particular patient exclusively to meet their individual conditions and needs”.

Crucially, the regulations also say that custom-made medical devices must always be produced on the basis of a written prescription provided by a suitably qualified medical professional.

This could cover products made using additive manufacturing techniques and customised for individual patients, but the definition in the regulations doesn’t stop there. They go on to exclude two categories of medical device product from the custom-made definition:

- Mass-produced medical device products which are adapted to the specific requirements of a patient

- Mass-produced products manufactured as per a written prescription

As many customisable medical device products made using additive manufacturing techniques could be defined as mass-produced, they may fall under the above two exclusions. This would mean the new EU MDR does not treat them as being custom-made.

Without further guidance or clarification, the above definition indicates that the label of custom-made, and the resulting regulatory requirements, can only be applied to products made from scratch.

What Does This Mean for the Use of Additive Manufacturing Techniques to Customise Medical Device Products?

In simple terms, more information is needed. Let’s take as an example a mass-produced implant that is 3D printed so that each product is unique. Will it be regarded as custom-made or not?

Under the current definition, it won’t be treated as a custom-made product which might mean it needs its own CE mark and clinical evidence.

In other words, as with many other areas of the new EU MDR, more information is needed.

Solutions Exist

That said, there are solutions when you look at other jurisdictions.

In the US, for example, FDA guidance says customised medical devices can be based on a standard size template for regulatory approval.

Alternatively, the manufacturer can specify a performance or design envelope within which the product will be manufactured. This allows for patient-specific customisation of the medical device within the approved performance/design range.

So, while there are uncertainties now with the new EU MDR, the challenges can be overcome to the benefit of patients as well as to medical device manufacturers looking to expand their product customisation offerings.

Comments are closed.