News

Celebrating Wins Together: SL Controls Company Outing 2024

Members of the SL Controls team got together recently in Athlone for our annual company outing.

The day started with a puzzle solving challenge called Beat the Box organized by Orange Works. We had to work together as a team to identify the code which turned out to be our employee appreciation tagline: Celebrating Wins Together.

We then boarded a replica Viking ship for a cruise down the Shannon to Killinure Chalets where a delicious barbecue was waiting for us in relaxed and rustic surroundings. We then returned to Athlone where the party continued.

Shauna Ryan, Director of People & Culture at SL Controls, said: “We operate a remote and hybrid working model at SL Controls, so events where we come together in person are highly anticipated, especially when they are non-work related.

“This is not the first time we have travelled to Athlone and the afternoon and evening didn’t disappoint. It was great to see old friends and meet new ones, and to spend time in each other’s company.

“Thanks to the various organizations involved in running the activities and the SL Controls team who organized the event. Our next opportunity to get together will be our first NNIT Region Europe Summit in Copenhagen in October. We are very much looking forward to meeting and getting to know our NNIT colleagues!”

SL Controls Teams Compete in Summer Activity Challenge

Promoting good physical and mental health is an important priority for SL Controls, and it never hurts to add in a bit of friendly competition. So, throughout the month of June, 30 members of the SL Controls team split into five teams to compete in our summer activity challenge.

Participants could engage in any type of physical activity, anytime and anywhere. All they had to do was log their activity on the Strava app so we could award points. The more minutes the participants were active, the more points they received.

There was a wide range of activities and sports that team members took part in, including running, walking, hiking, swimming, cycling, kayaking, pilates, yoga, HIIT workouts, and golf. Photos taken by some of the participants are below.

But there could only be one winner – the Le(g)s Misérables team who claimed a comfortable victory by the end of the month.

Norma Mulligan, People & Culture Executive at SL Controls said: “The first thing to say is well done to all the participants in this year’s summer activity challenge at SL Controls. And congratulations to the winning team – Riley Moloney, Darragh McMorrow, Deirdre Loughlin, Fergal Quinn, and Bharat Varada. We also need to give a shout-out to Dermot McMorrow who was named the most active individual following an impressive performance in the second week of the challenge.

“Staying physically and mentally fit and healthy doesn’t stop at the end of June, though, so we have also used the event to encourage all members of the SL Controls team to stay active and keep up the good work from the challenge.”

Inspiring the Next Generation of Engineers in Tipperary

SL Controls engineers recently completed an engineering education program with 5th-class primary school pupils at Youghalarra National School in Nenagh, County Tipperary, Ireland.

SL Controls Systems Architect Volker Winhausen and Senior Validation Engineer Andrew Ryan took part in the program which is run by STEAM. STEAM is an organization that partners with industry to inspire children in science, technology, engineering, arts, and maths with interactive presentations and practical activities.

Increased Confidence

Andrew and Volker guided the primary school pupils through the 10-week program and said it was great to see confidence levels increase.

Andrew said: “There was a huge difference in response between the first class we had with the children and the last class. In the last class, confidence levels were much higher, and the children were delighted to get their final certificates. It was great to see their confidence grow, and they were not afraid to throw their hands up to give answers to questions. The whole experience was good for us, good for the school, and good for the kids as well.”

Volker agreed: “The kids were a bit reserved at the start but afterward when they got to know us, they warmed up, asked questions, and gave answers. It was good learning for us as well.

“I didn’t know what to expect at the start. What I really like about STEAM is the nice change between the PowerPoint presentations and the practical exercises. I liked the enthusiasm of some of the kids, and you can see they get excited about engineering. But there is the other side too, like when we asked who had built a paper plane before. Only about six from the class of 14 had built a paper plane. I found that surprising.

“Some of the kids got hooked on a topic and even tried things over the weekend at home. One guy built a catapult that must have taken him all weekend. We got the most enjoyment from the electronics session, where the children used Play-Doh to build circuits. I didn’t even know you could do that with Play-Doh, but the children got their light bulbs all lighting up which was really cool.”

From Germany to Tipperary

Andrew added: “With some of the practical exercises, you could see the kids trying to find the right solution, and you could see lightbulbs going off in their heads. They definitely were taking on board the high-level messages.

“At one point, Volker went back to his own primary school days to explain a point about current flows. So, something taught in Germany was brought back to a class in Tipperary, but that’s how you get things across. The children could understand it completely with that example from Volker.”

Andrew said the experience was worthwhile and he recommended it to other engineers.

He said: “My advice is to do it, as it’s a great experience. At the start, no one knows what they are getting into – the kids, the teacher, ourselves. But in the end, everyone gets something out of it, especially the children. My advice is to do it if you get the opportunity.”

Reinforcing Our Commitment to Diversity, Equity, and Inclusion

Diversity, Equity, and Inclusion (DEI) is a central priority for SL Controls, so we took the opportunity last week on National Diversity and Inclusion Day to reinforce our commitment to making positive changes.

This included launching company-wide unconscious bias training as well as our second DEI employee survey. The survey aims to capture the views of all colleagues to help guide future DEI activities and initiatives.

On the day our DEI Group gathered for an in-person meeting at our Limerick office where we enjoyed a lunch featuring Indian cuisine. It was wonderful to come together, discuss DEI issues, and sample dishes from our colleagues’ home cultures.

Shauna Ryan, Director of People & Culture at SL Controls said: “DEI is an ongoing, daily focus for SL Controls. It was important to mark National Diversity and Inclusion Day, but it is more important to ensure we continuously strive to make real and impactful change.

“There are so many examples in society where DEI standards fall short. At SL Controls, we strive to both set an example and learn from the best practices of others. Central to this is understanding the opinions and experiences of our diverse team as we all have a contribution to make when it comes to diversity, equity, and inclusion.”

International Women in Engineering Day 2024 – Enhanced by Engineering

International Women in Engineering Day takes place this weekend, on Sunday. The theme for International Women in Engineering Day 2024 is Enhanced by Engineering, so the focus is on women who have enhanced by engineering “people’s everyday lives and are helping to build towards a brighter future”.

SL Controls is an engineering company. The majority of our customers are in the life sciences sector, so we work with some of the world’s largest medical device and pharmaceutical companies, i.e., companies that develop and manufacture products that diagnose, treat, and transform the lives of patients.

We asked some of the women in SL Controls their thoughts on working for customers in the life sciences sector.

Part of Something Bigger

Nav Dharni, Project Manager: “Sometimes we look at these medical device companies or pharma companies and we’re just familiar with the big names, the brands, and the products. I think it’s really nice to see everything that happens in order to get that product out, that journey of understanding the industry better.

“Although we are not directly involved with patients or the customers who are buying the products, it’s nice to see you are involved in helping people and advancing technologies within the health sector. It’s nice to know you are part of something bigger.”

Saoirse Kearse, Software Quality Engineer: “I’d say the best thing about working in the life sciences sector is the fact you can impact people’s quality of life in a positive way, especially when they badly need it. It gives you that satisfaction that you are actually benefiting people.”

Privilege

Deirdre Loughlin, Quality Lead: “Although I am not an engineer, it is a privilege to be part of a company that helps make products that enhance people’s lives. Every day our engineers are working to make people’s quality of life better which is something to be really proud of.”

Blessing Nwachukwu, Systems Engineer: “Listening to the problems and finding digital solutions that can solve the problems – it’s the ever-evolving solutions that we work on and develop for our customers. The solutions enable creativity and innovation, and they are always intriguing.”

Jisa Varghese, Systems Engineer: “… what I find most rewarding in working with life sciences clients is the seamless integration of technology and pharma. It is interesting to develop new tools and applications as this field is constantly evolving and has lots of potential. It is also exciting as there are different varieties of technologies I get to work with.”

Diane Maher, Systems Engineer: “Knowing I’m making an impact in an important sector [is the best thing about working in the life sciences sector]. I know I have to maintain a high level of accuracy and detail and I like practicing this every day by default.”

Connecting the Dots

Shauna Ryan, Director of People and Culture: “One of the really enjoyable things about my role is getting to talk to our employees about the work they do, the projects they work on. They have a passion that is infectious and inspiring. It is a passion for the technologies they work with and the problems they are resolving – of course, they are engineers. But there is also a passion for the fact we operate within the life sciences sector.

“We don’t manufacture or develop medicines or medical devices at SL Controls. What we do is improve manufacturing processes. That work helps our customers get their healthcare products to a greater number of patients around the world. Connecting the dots between those products and the work I do in human resources or the work our engineers do on a pharmaceutical production line gives me a real buzz. It’s rewarding.”

Meet the Team: Nav Dharni

1. Describe your job as if you were explaining it to a five-year-old.

I’ll describe my job as kind of like baking a cake. So, in order to bake a cake, a project manager would have to see how we get to the end goal, which is we want a cake, but in order to get there, we need the starting pieces. We need to make sure we have our ingredients, then we need to know how to bake it.

And in all of this, it requires planning – that’s a key part of the job, understanding what may also go wrong.

You get your ingredients, you know how long the cake is going to take to make, you follow the instructions, and a project manager does something very similar with projects. You know what your end goal is and it’s about getting all your pieces aligned to see how you can achieve that and then tracking it as you’re going along.

In the same way as you’re baking your cake, you’d give it a quick try to make sure it tastes good. Then you put it into the oven, checking it regularly to see how it’s baking. And then you have your end product and hopefully, it’s a wonderful cake and a completed project.

2. What types of projects are you working on at the moment?

At the moment I am on a project team that I would describe as delivering EPC projects – E for engineering, P for procurement, and C for construction. It involves taking engineering projects from conceptual design all the way to purchasing the equipment and then doing the installation and construction work.

3. How did you get into the industry?

I followed quite a traditional path. I went to university and did my degree and master’s in chemical engineering. I was eager to begin my career with a foundation of technical experience, so I joined a graduate scheme. I followed a couple of technical rotations during the 18-month scheme and then I just kind of took it from there.

I went into project engineering roles and the skill set that I was developing and the roles I enjoyed the most were in the field of engineering project management. So, taking my technical understanding of projects and applying that knowledge to facilitate a group of SMEs in the delivery of a project.

I was in the UK at the time and working in the gas and electricity industry. Life then took me to the United States where I started working for a multinational medical device corporation in project lead roles and project management.

Medical devices was a totally new industry for me – I went from utilities, gas, electricity into medical devices. But that’s the great thing about engineering – you can apply your experience and knowledge across different industries.

4. What is your proudest moment (work life or personal life)?

I would say getting first-class honors in my master’s, I think that was a proud moment, to be in the top percentile of my graduate cohort at Aston University in Birmingham, England.

5. What’s the best advice you could give to someone thinking of coming into this industry?

Don’t let the stereotypes or your assumptions get in your way. I think engineering as a whole is a really exciting place to be, especially now with the advances that are coming about with new technologies and machine learning and AI – I think AI is definitely a big part of the future.

For people who are thinking about a new career or what career they want to do, I would say one thing that is beautiful about engineering is it’s so diverse. There’s so much you can do. Even if you have studied one particular discipline of engineering, you’d be surprised how many other roles or jobs you can go into. I think engineering gives you a basis of really good core skills that can advance you for a successful career.

Engineers typically think with a mindset that I think a lot of employers seek. You are able to think abstractly, your logical reasoning is risk averse, and you’re very pragmatic – I think these are things that employers do like.

I also think in engineering you develop quite strong interpersonal skills, which are really important as well. Typically, you are working with all sorts of people in multidisciplinary teams, so your communication skills are also advanced.

6. Outside of work, what are you most passionate about?

I love to travel. I love to explore different cultures, learn about them in an experience where I’m actually in the country.

I don’t know if it’s a passion, but I definitely do it a lot – I love to eat out. I love to try different restaurants. And I like to cook. I like to, you know, chef it up sometimes in the kitchen.

So, food, food, food, and travel.

7. What’s the best thing about working for life sciences customers (pharma, MedTech, etc)?

I think it’s really interesting to be able to see how much work goes on that you would never realize. Sometimes we look at these medical device companies or pharma companies and we’re just familiar with the big names, the brands, and the products. I think it’s really nice to see everything that happens in order to get that product out, that journey of understanding the industry better.

Although we are not directly involved with patients or the customers who are buying the products, it’s nice to see you are involved in helping people and advancing technologies within the health sector. It’s nice to know you are part of something bigger.

8. What is the best thing about being on the SL Controls team?

In my experience so far, SL Controls is an organization that really does care about its employees. I think the relationships that are forged, you don’t always see that within the corporate world or in really large organizations. People are very supportive here. I think that’s a big asset to the company that they really want to support your development.

Meet the Team: John Downey

1. Describe your job as if you were explaining it to a five-year-old.

I manage projects for various medical and life science clients. My role involves supporting commercial activities, understanding customer requirements, and building a project team and scope to deliver to those requirements.

2. What types of projects are you working on at the moment?

My project areas at the moment would be focused on digital transformation. I am involved in the consultation, design, development, and validation of OT (operational technology) projects or OT systems for use cases such as OEE (overall equipment effectiveness), batch control, paper-to-glass, and statistical process control.

Digital transformation is a priority with all customer organizations I work with. Customers have resources and teams in place to support digital transformation initiatives, where they identify the main pain points that can be solved by digital transformation.

The main drivers for implementing any digital transformation project are increasing compliance, meeting regulatory requirements, and the cost-effectiveness and efficiency of the client organization.

3. How did you get into the industry?

I came into the life science industry and into SL Controls following 19 years in electronics manufacturing. My first role was a project management opportunity in SL Controls focused on an Industry 4.0 consultancy engagement.

I found the data-driven approach in life sciences was emerging in some respects, whereas the data-driven approach was already prevalent within the high-volume electronics industry. So, I saw big opportunities within the life sciences sector for the integration of systems to provide insights and enhance data-driven decision-making capabilities.

4. What is your proudest moment (work life or personal life)?

Having two kids and seeing them grow, learn, and develop is what I’m most proud of.

5. What’s the best advice you could give to someone thinking of coming into this industry?

Probably the best advice I could give is to use your experience or education. Especially if you are new to the sector or you are transitioning into the sector, don’t forget the experience and education you have.

Ask lots of questions. Leverage the resources that are available to help you grow within the business. Utilize the strong mentor network within SL controls to grow in your career.

And have fun along the way.

6. Outside of work, what are you most passionate about?

Enjoying time with family and getting regular exercise, which is good for mental health, particularly in the hybrid working environment. I also help coach the local under-11 soccer team. That’s very rewarding as well.

7. What’s the best thing about working for life sciences customers (pharma, MedTech, etc)?

I think being able to see the vision of a project being implemented in a healthcare setting and connecting that vision with the benefits at the end of the project. Also, in everyday life when you see the client’s products or services benefiting patients and being able to connect that back to projects that SL Controls has delivered – those are the best things.

8. What is the best thing about being on the SL Controls team?

There’s a great team culture within the organization. It’s supportive of individual needs and your career path or your career direction.

But probably the best thing is seeing the growth of the teams and individuals within SL Controls along the journey of projects and client engagements.

Celebrating Cultural Diversity at SL Controls

May 21st is World Day for Cultural Diversity 2024, an initiative to highlight the richness of the world’s cultures and encourage intercultural dialogue. To celebrate, we asked the SL Controls team to share information and reflections about their country and culture. Watch the video now.

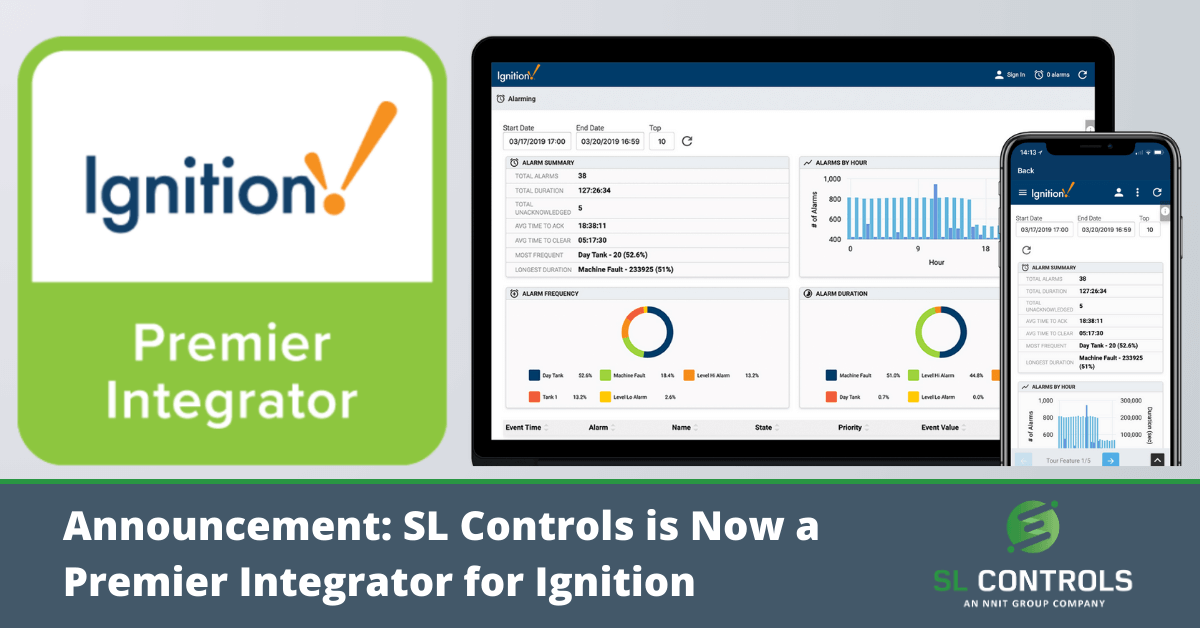

SL Controls Achieves Premier Integrator Status for Digital Transformation Platform Ignition

SL Controls has been certified as a Premier Integrator for Ignition, the digital transformation platform for industrial automation. Ignition by Inductive Automation features flexible and fully customizable SCADA and MES (manufacturing execution system) functionality with comprehensive integration capabilities.

NNIT Group company SL Controls is one of only three Ignition Premier Integrators in Ireland and the only Premier Integrator with expertise across the life sciences sector, including both the pharmaceutical and medical device industries.

Frank Quinn, Digital Transformation Executive at SL Controls, said: “We have been working with the Ignition platform for several years now integrating it into customer facilities in the life sciences sector. It is a digital transformation platform that stands out from the competition because of its broad range of features, unlimited integration capabilities, minimal learning curve for end users, and straightforward, cost-effective pricing model.

“Ignition is also highly customizable, enabling our engineers and systems architects to develop solutions that not only meet the specific needs of our customers but also deliver fast results and tangible returns on investment.

“Those tangible returns on investment come from productivity, efficiency, and OEE improvements. Specific objectives we help our customers achieve include paper-to-glass transitions, automating processes, and making better use of data, as well as performance improvements specific to the life sciences sector, including batch release by exception.”

The Power of Ignition Combined with SL Controls Expertise

Our expertise at SL Controls includes over 20 years of experience delivering system integration and manufacturing process improvement solutions for customers in the life sciences sector. This extensive industry, compliance, and manufacturing process knowledge, combined with the power of the Ignition platform, means we can deliver fast results, measurable performance improvements, and tangible returns on investment for our customers.

The power of the Ignition platform comes from its comprehensive integration capabilities, SCADA functionality, and MES features. It bridges the gap between operational technology systems on the factory floor and enterprise-level platforms such as ERP systems.

The real-world benefits for customers in the life sciences sector include:

- Faster batch release processes.

- Seamless paper-to-glass transitions.

- Productivity gains through automation and process improvement.

- Streamlined and cost-effective regulatory compliance.

- Ability to reallocate skilled resources from repetitive tasks to value-adding tasks.

- OEE improvements across the factory floor.

- Better integration and collaboration between enterprise-level and operational-level functions.

- Enhanced oversight and better quality, data-driven decision-making.

Delivering for Life Sciences Sector Customers

Inductive Automation operates a rigorous assessment process when certifying Premier Integrator partners. Only 2 percent of Ignition integrators have Premier status. Chris Fischer, Integrator Program Manager at Inductive Automation, congratulated SL Controls on achieving the certification.

Chris said: “I’m very pleased to welcome SL Controls as a Premier Integrator of Ignition software. SL Controls have distinguished themselves by doing excellent work with leading companies in the life sciences sector, and by expanding the knowledge and expertise of their team. I sincerely look forward to working with SL Controls over the coming years.”

Darragh McMorrow, Commercial Director at SL Controls, said: “We look forward to continuing to build on our relationship with Inductive Automation, and we are grateful for the support we have received from the team.

“We also look forward to helping more of our customers achieve digital transformation success in their manufacturing operations by implementing and integrating the Ignition platform.”