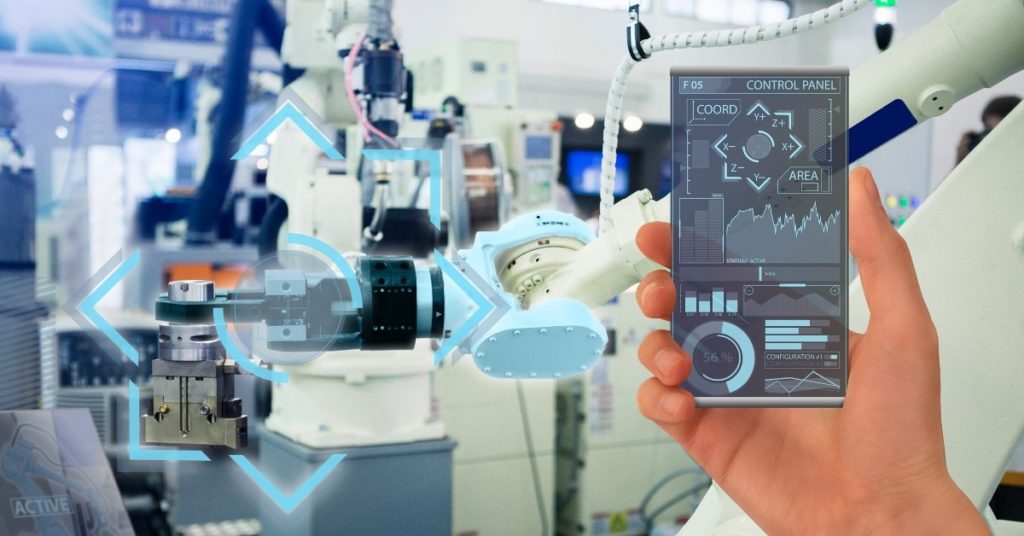

11 Manufacturing / Ramp Strategies that Smart Factory Solutions Facilitate

The manufacturing / ramp strategies in use on your production lines are crucial to the success of your business. Specifically, they enable you to profitably produce the required volume of products and, in most cases, leave room for growth in the future. Smart factory solutions allow you to take this a stage further by adding …

11 Manufacturing / Ramp Strategies that Smart Factory Solutions Facilitate Read More »