Additive manufacturing involves manufacturing a product by fabricating it layer by layer, building it up. It is sometimes referred to as 3D printing, although the technologies involved and the processes that are available are now more advanced than the term 3D printing indicates.

All additive manufacturing techniques differ from traditional manufacturing techniques that produce components/products by removing material (such as in machining) or shaping material (such as extrusion or blow moulding). Instead, additive manufacturing builds up a component or product one tiny layer at a time.

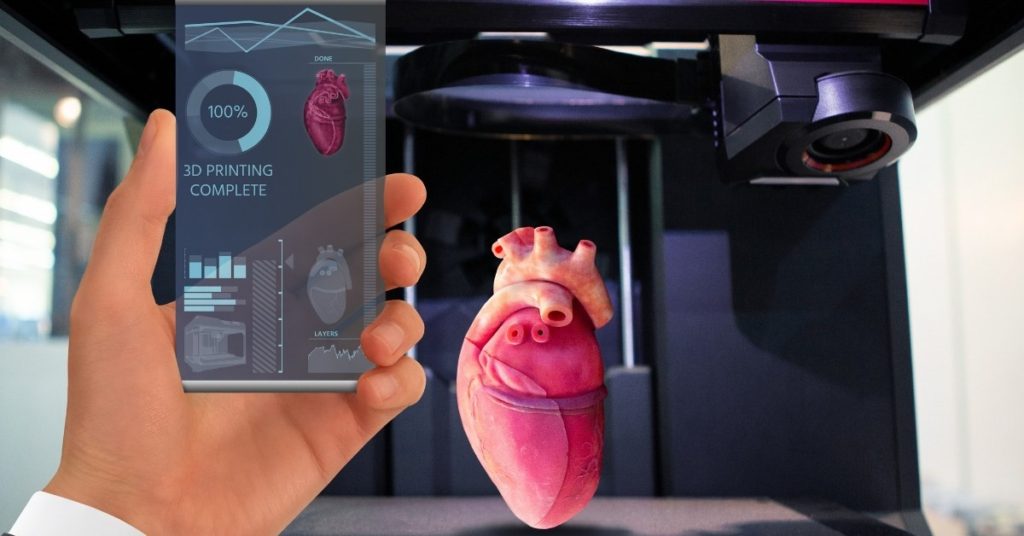

The Benefits of Additive Manufacturing to the Medical Device Industry

- Can produce almost any type of shape, including highly complex and intricate shapes

- Reduces the need to manufacture a product in parts. Instead, additive manufacturing lets you, in many situations, produce the component/product in a single piece, eliminating the need for parts assembly completely.

- The above creates higher quality products

- The point above also makes it possible to create shapes, components, and products that are not possible using other manufacturing techniques

- Can significantly speed up the prototyping process as changes can be implemented and produced quickly

- The speed of making changes also makes additive manufacturing ideal for mass customisation right down to manufacturing batch sizes of one.

Current Applications of Additive Manufacturing in the Medical Device Industry

- Creating models of a patient’s anatomy that surgeons can practice on before real surgery takes place

- To make patient prosthetics

- Manufacture of patient-specific implants

- In dentistry to make dentures and implants

Additive Manufacturing Processes

There is a range of additive manufacturing processes available depending on the component/product you need to manufacture. Those processes include:

- Powder Bed Fusion

- Vat Photopolymerization

- Directed Energy Deposition

- Binder Jetting

- Material Extrusion

- Material Jetting

- Sheet Lamination

Powder Bed Fusion

Powder bed fusion uses melted powder, making it possible to fuse particles together and build up a 3D object layer by layer. In simple terms, material powder is rolled or spread over the previous layer before being fused together with heat.

The main techniques involved are:

- Electron beam melting (EBM)

- Direct metal laser melting (DMLM)

- Directed metal laser sintering (DMLS)

- Selective laser sintering (SLS)

- Selective laser melting (SLM)

- Selective heat sintering (SHS)

Binder Jetting

In the binder jetting additive manufacturing process, powdered material is added to the product in layers. A liquid binder, or adhesive, is applied to each layer. The print head deposits the powdered material and the liquid binder alternately, building up the component or product.

Vat Photopolymerization

In the vat photopolymerization process, a component or product is made from a vat of liquid photopolymer resin. This process can produce components with smooth surfaces and fine details.

It uses a build platform located in a vat of liquid polymer, with the build platform moving down as each new layer is added. In other words, vat photopolymerization works from the top down.

As the build platform moves down each layer, a UV light source cures the photopolymer resin.

Directed Energy Deposition

Directed energy deposition features a nozzle that moves around multiple axes – up to five. This nozzle deposits material onto the component or part in layers. This material can either be in the form of a wire filament or powder. The powder can be metal, ceramic, or polymer.

This material is then fused to the component or part using a laser, plasma arc, or electron beam.

Material Extrusion

Material extrusion is the most common type of 3D printing technology, not least because it is inexpensive and fast.

It involves the material, usually a polymer, passing through a heated nozzle before being added/fused to the component or product as the next layer. The nozzle moves horizontally across the component/product to add the layer, with the build platform moving vertically so the next layer can be added.

Material Jetting

Material jetting works on similar principles to an inkjet printer. A nozzle jets polymer onto the component/product to build up each layer. UV light then cures or hardens the material to finish the layer before moving to the next one.

Sheet Lamination

There are two main sheet lamination processes:

- Ultrasonic additive manufacturing (UAM) – the material is in the form of ribbons or sheets of metal. They are bound together, layer by layer, using ultrasonic welding. The materials that can be used include stainless steel, titanium, aluminium, and copper.

- Laminated object manufacturing (LOM) – this process is similar to the above except the material used is paper. It is bonded layer by layer using adhesive. The result resembles a 3D plywood object.

The Future

Additive manufacturing technologies continue to advance, with potential medical applications in the future that will dramatically enhance patient care and improve treatments. That said, additive manufacturing also offers benefits and opportunities today.

Comments are closed.