Manufacturing technologies are advancing at a faster rate than ever before. In such a fast-paced and busy environment, it can be hard to cut through the information and noise to get to what really matters and what will really make a difference.

In other words, the things that will improve your competitiveness in the marketplace and your bottom line.

Industry 4.0-related technologies are driving much of the changes that are currently taking place in manufacturing. This applies in all sectors, but it is particularly important in high-specification and highly regulated industries like pharmaceutical manufacturing and medical device manufacturing.

If you’re in one of these or a related industry, here are seven Industry 4.0 trends that will influence manufacturing in 2019.

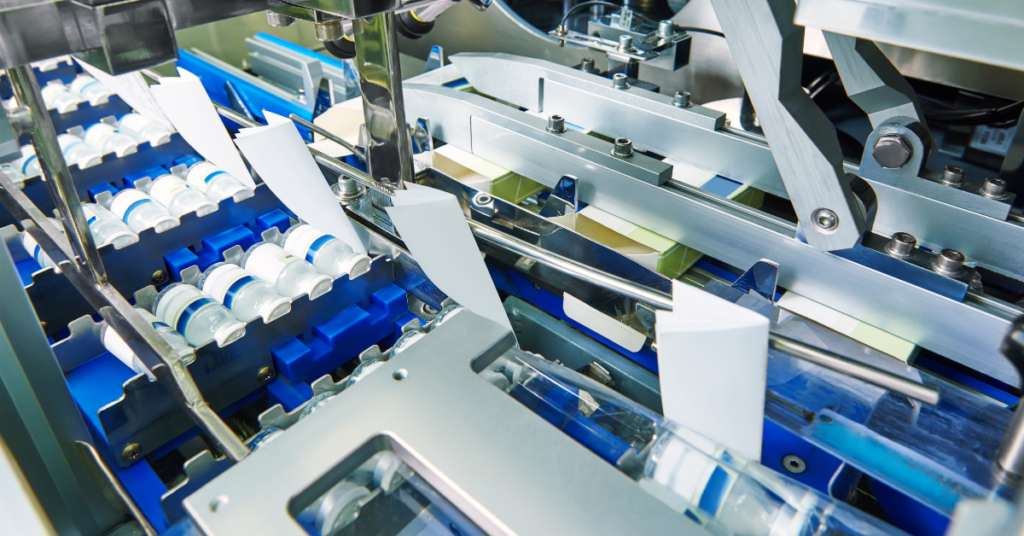

1. Factory Automation

The are many reasons for companies moving towards Factory Automation technologies. This includes making production lines more efficient, making more effective use of resources, and improving productivity.

Recruitment challenges are also a factor, with manufacturers looking to technology as a solution.

Remaining competitive in fast-changing marketplaces is also a driving factor for increasing numbers of companies adopting Factory Automation solutions.

There are challenges, not least the challenge of integrating legacy systems and platforms with new equipment and technologies. These challenges are not insurmountable, however, so Factory Automation will be a feature in manufacturing not just in 2019, but for many years to come.

2. Virtual, Augmented, and Mixed Reality

Virtual, augmented, and mixed reality can be applied in manufacturing facilities in several ways. This includes product design, production line development, driving OEE improvements, technical and engineering support, training, team collaboration, inventory management, and more.

These technologies help businesses work more effectively while also making them more efficient. An example of their application includes using augmented and virtual reality to design a new production line or product, perfecting it in the virtual world before real-world prototyping or production begins.

Another is an engineer providing remote engineering support on a specialist machine on your production line using mixed reality. In this situation, your facility and engineer can be located on the other side of the world to the technical support engineer.

3. Digital Twin Technologies

Digital Twins are an emerging technology that will become an increasingly important tool in manufacturing facilities. A Digital Twin is an exact virtual replica, updated in real-time, of a physical object, process, or product.

The applications for this technology in manufacturing are far-reaching. One example is having a Digital Twin of a piece of equipment – or your entire production line – where engineers can run simulations and where machine learning technologies can predict breakdowns, plan maintenance schedules, improve OEE, and more.

4. Increasing Convergence of IT and OT

In the past, IT and OT were typically separate in manufacturing businesses:

- IT – supporting management, sales, accounting, purchasing etc

- OT – monitoring and controlling equipment, tools, and other assets on the factory floor

In fact, not only was OT traditionally separate from IT, individual systems and equipment within the OT infrastructure also existed in their own silos.

The move to intelligent manufacturing technologies and big data now makes it possible to integrate machines, platforms, and systems across all units of the business. This drives efficiencies, enhances business oversight, improves product quality, makes customer service more effective, and increases productivity.

There are challenges, of course, including dealing with compatibility issues and ensuring systems are secure. Overcoming these challenges is possible, though, presenting considerable opportunities for manufacturers.

5. Further Move Towards Digitalisation

Digitalisation is sometimes referred to as digital transformation. It involves using digital technologies to adapt or transform your business into a digital business.

In manufacturing, this means incorporating many of the points above so that systems and equipment are integrated throughout every process, chain, unit, department, and facility in your business.

6. Increasing Use of Cobots

Some research predicts the cobot market will grow from USD $710 million in 2018 to USD $12.3 billion by 2025. One of the reasons for this is the fact today’s cobots are more affordable as well as being safer, more adaptable, and more compact.

Cobots create opportunities for manufacturers to improve their production lines, increasing productivity while keeping employees safe.

7. Small Batch and Mixed Manufacturing

Many of the technologies mentioned in the points above, as well as other technologies and processes, mean it is now possible for increasing numbers of companies to consider small batch and mixed manufacturing.

This creates opportunities for your production facility, letting you compete for a wider range of contracts.

There are other benefits too, including the possibility of offering customers individual product customisation options. This not only increases value, but also creates new business opportunities.

Final Thoughts

While the above is a whirlwind overview of some very advanced and technically complex technologies, it does show the opportunities that exist in 2019 and beyond for manufacturing companies with a forward-thinking and innovative outlook.