The Project

The project outlined in this case study involved integrating the PAS-X MES platform into a customer’s production line. The customer is in the life sciences sector.

SL Controls’ parent company, NNIT, was the lead on the project. NNIT provided full support for the integration process, including scoping, design, deployment, and validation.

The first phase of the project involved defining the processes that would benefit most from storing electronic batch records. It was also important to define Master Batch Record (MBR) process flows and ensure MBR compliance with CFR Part 11.

An issue was identified at this point in the project, as the process would require the manual entering of data into the PAS-X MES. This had a number of negative implications, including the resources that would be required, the limitations it would put on the system, and the increased risk of human error that manual data entry brings.

To move the project forward and find an alternative solution to manual data entry, it was necessary to identify the production equipment that could be connected to the PAS-X MES platform. This would also involve determining the type of connection that would be needed and the required network infrastructure design.

This is where SL Controls got involved in the project, as we have significant expertise in equipment systems integration.

Objectives

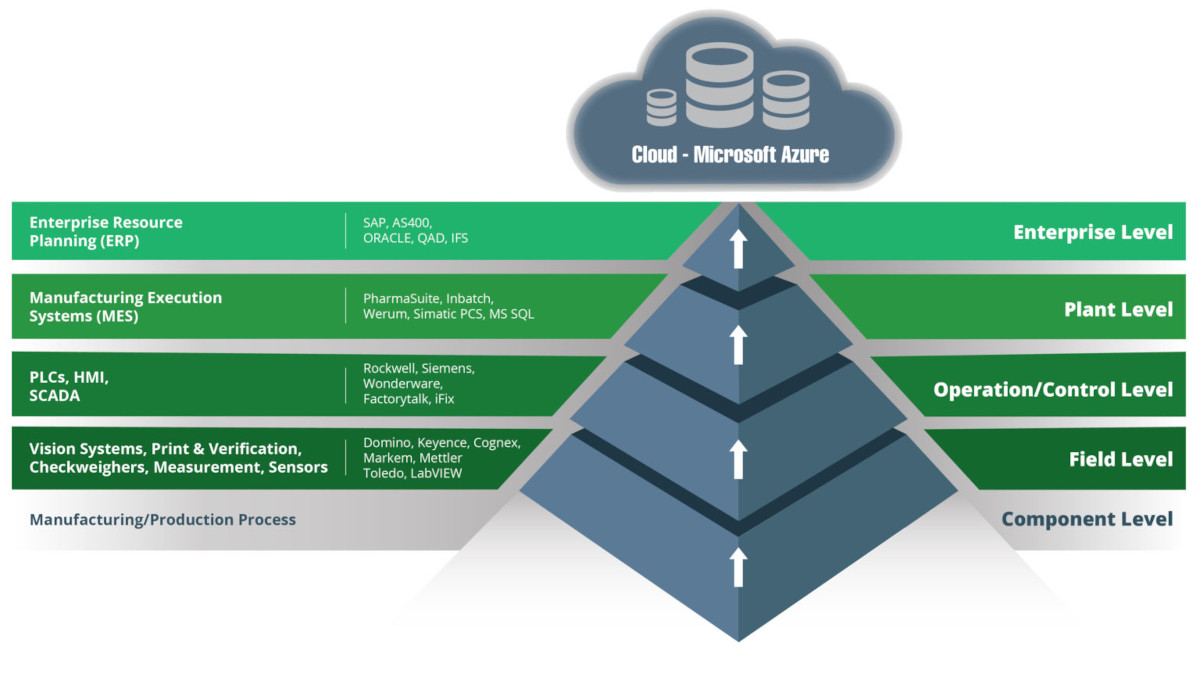

There are five Operational Technology (OT) infrastructure levels in life sciences sector production facilities.

At SL Controls, our main expertise is in levels 0 to 2, i.e., designing and developing SCADA systems, developing data historians, batch performance tracking, integration of manufacturing equipment, etc.

We also have extensive expertise in the integration of manufacturing equipment with MES systems, as represented in the Plant Level. It was this expertise that was required, so SL Controls engineers joined the wider NNIT team.

Our expertise fitted in perfectly, as this stage of the project involved the integration of production equipment with the PAS-X MES platform.

What We Did

Our engineers worked with the customer’s automation engineers, as well as equipment vendors and our colleagues at NNIT, to identify the best methods for connecting the production equipment to the PAS-X MES.

We also proposed changes to the existing OT/IT infrastructure to facilitate data collection and batch information download from the new MES. We supported the customer’s IT and OT engineers in the implementation of these changes.

Our robust solution enabled data handling from the equipment on the production line to the PAS-X MES and vice versa.

Results

- With our solution, the PAS-X MES could be implemented with the risk of data errors significantly reduced as manual data entry was eliminated from the process.

- The solution is also robust enough to cope with the demands of a high-speed, high-volume, highly regulated production environment.

- The solution is compliant, too, as it satisfies the regulatory requirements of electronic batch records.

- We also provided a full end-to-end solution for the customer, utilising the expertise in both SL Controls and NNIT.

Sven Savic, SL Controls Systems Architect, said: “The acquisition of SL Controls by NNIT means the two companies now offer complementary skills that enhance the end-to-end level of service that we can offer. This unique and highly effective approach to project delivery was demonstrated in the successful delivery of this PAS-X MES implementation project.”